Model Engineer Article (1st reference to Stuart Turner 1901)

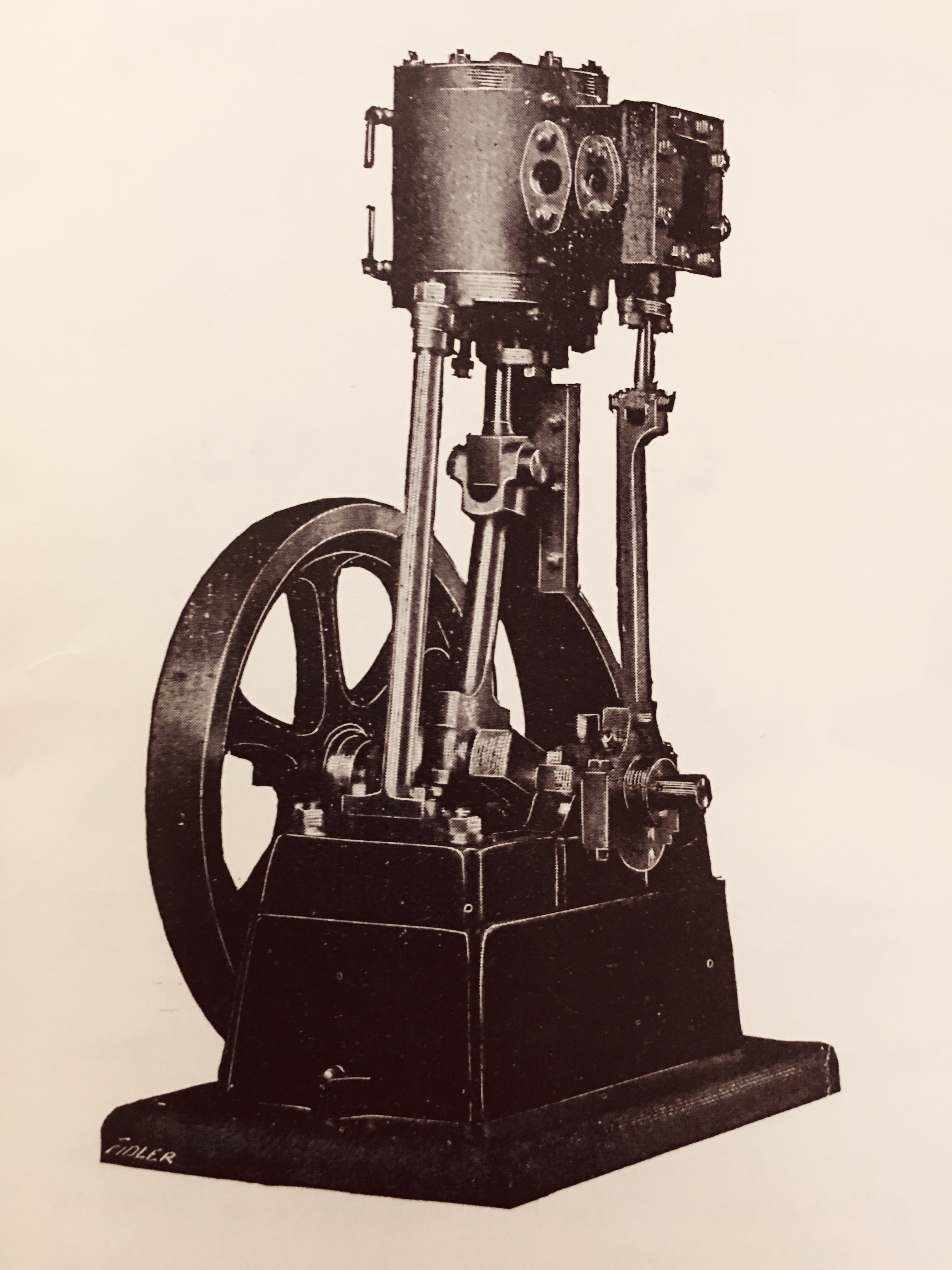

The accompanying photograph illustrates a new steam engine recently designed by Mr SM Stuart Turner, engineer, Shipton, Henley-on-Thames to suit those requiring a reliable motor of small power. Although of light weight - 18 LBS finished, including a heavy boxbed and flywheel, no strength has been sacrificed.

We are informed that the engine from which our photograph has been taken has been thoroughly tested and 1/4 b.h.p was easily obtained at 1000 revs per minute at 50 lbs. steam pressure. The cast-iron parts are guaranteed to be soft and sound, ample metal being left for machining. The gun metal parts have large area, the bearings and crank brasses are left solid, so that they can easily be machined and drilled out this avoiding the troublesome operation of setting for boring. The crankshaft, connecting rod, piston and crosshead and eccentric rod, are of the best cast steel, of a specially solid quality, and being cast accurately to shape require very little machining. One particular feature of the set is that the whole of the machine work can be done on a 3in lathe, the only part requiring the use of the gap being flywheel, and this will double be appreciated by amateurs possessing a small lathe only. The engine is shown without reversing gear but castings for this can be supplied at small extra cost. continuous lubricating fittings can be arranged to suit any particular purpose. A special eccentric strap and pump castings can be supplied when required. If required for launch work the weight can be reduced over 25 per cent by omitting the boxbed and using a disc in place of flywheel. Sample finished engine has been submitted for inspection, in which we can commend the sets of casting to those of our readers, who require to build a useful engine at a moderate cost. Mr Stuart Turner will be pleased to reply to any inquiries.