- © 2018 Steve Allen Contact Me 0

THE

"JAMES COOMBES'

A Table Engine

Bore: 1 in.

Stroke: 2 in.

Price

£212

Height. 14 1/8 in.

Contents:

Cast Iron - Baseplate, crosshead guides, pedestal, pulley, crank, cylinder, valve chest and cover, top and bottom cylinder covers, piston, 7 in. flywheel.

Brass - Slide Valve, eccentric strap, valve operating block, glands, conrod bush, crossheads, crankshaft bearings.

Steel - Crankshaft, connecting rod, eccentric sheave, eccentric rod, clevis, crankpin, piston and valve rods, all material for valve gear and beam pivot.

Sundries - Detailer drawings, gaskets, "O" ring, gland packing, fixings pack.

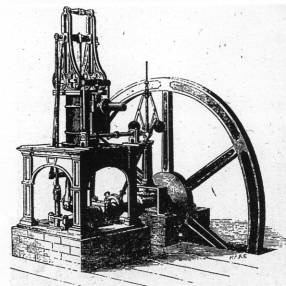

The table engine layout is a method of reducing the floorspace an engine takes up. The cylinder is placed on a table structure, below it is the crank. To pass the movement above the cylinder to the crosshead, above the cylinder, the conrod is much more complex. A rod is connected to a bar that spans the width of the cylinder and two connecting rods, connected to each end of the spar pass up through slots in the table and connect to a bar running through the crosshead. The crosshead runs in slots machined into two triangular support frames. The crosshead slides in the James Coombes design but some feature rollers that run in the support frames. Valve gear is the same as for the Beam engine but with a much shorter eccentric rod. The two supports towering above the cylinder combined with the two connecting rods give this engine a very arhitectural look, some engines were very extravigant in the design of the casting leading to another variant of this engine type, the Cathedral Engine. The running of this engine looks a bit odd to start with, the occilating connecting rods eaither side of the cylinder. After a while it becomes a bit hypnotising.

Common Govenor

As well as a series of common engines, Stuart also created a set castings for a governor to be used on all the range. Detailed plans how to machine the castings to match each of the engines.

Driven by a spring belt the govenor is fully working. It links to a working steam valve.

Please Consider Making a Donation