- © 2018 Steve Allen Contact Me 0

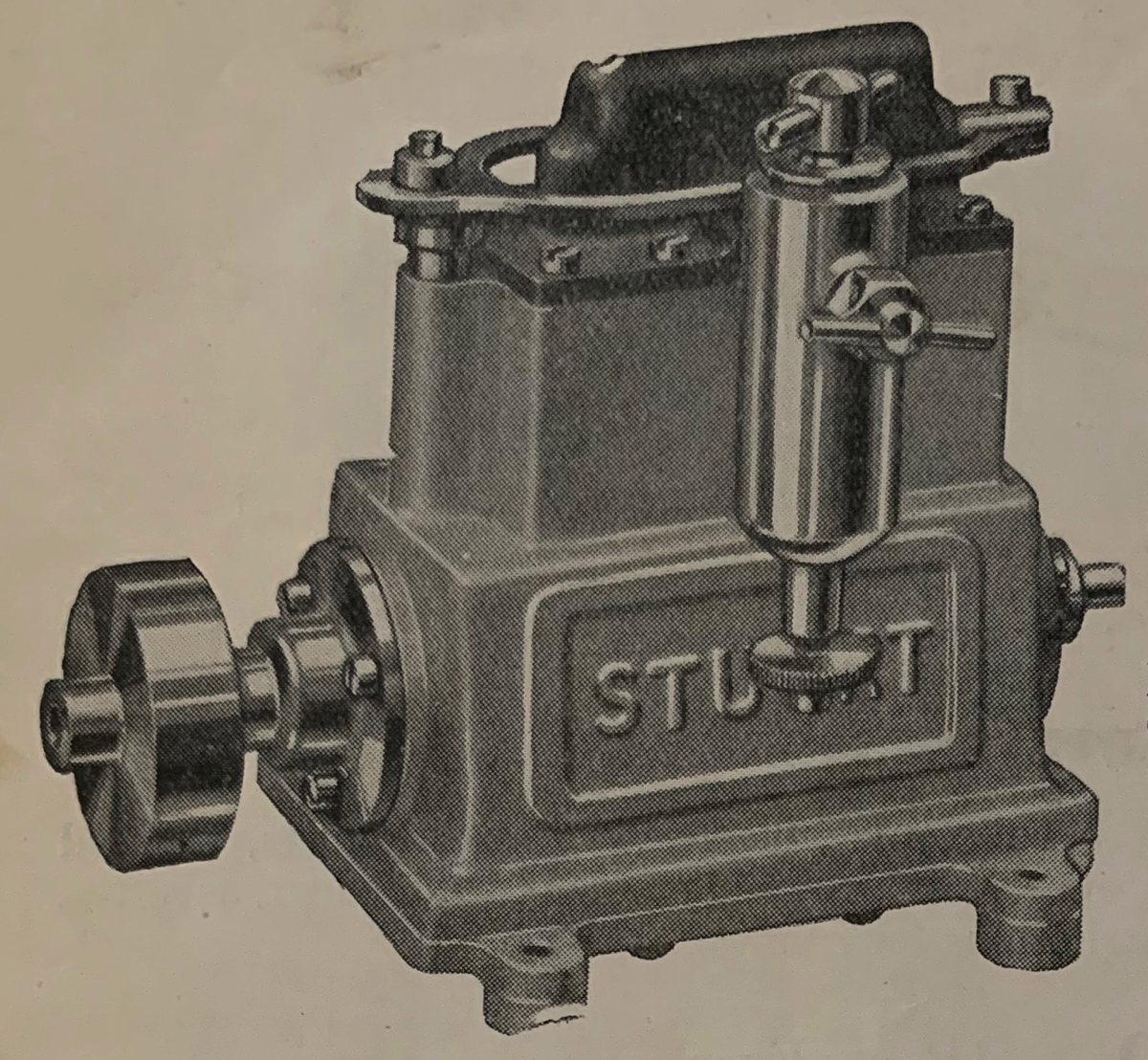

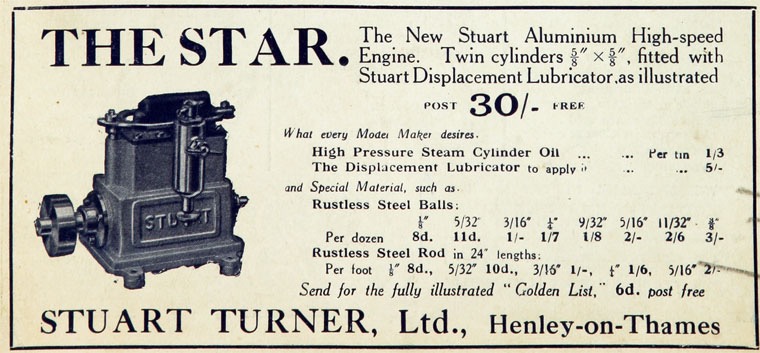

The New STUART "STAR."

Ultra Lightweight

Engine

Twin Cylinders, SingleActing

Bore-5/8-in. Stroke, 5/8-in

Die cast Aluminium body with

hard brass cylinder liners

Hard brass Featherweight

pistons forged double throw

crankshaft Rustless steel piston

lubricator valve. Displacement lubricator.

Weight 18-ozs.

Height 3 3/4-ins.

Length overall 4 3/4-ins.

Width(extreme) 2 3/4-ins.

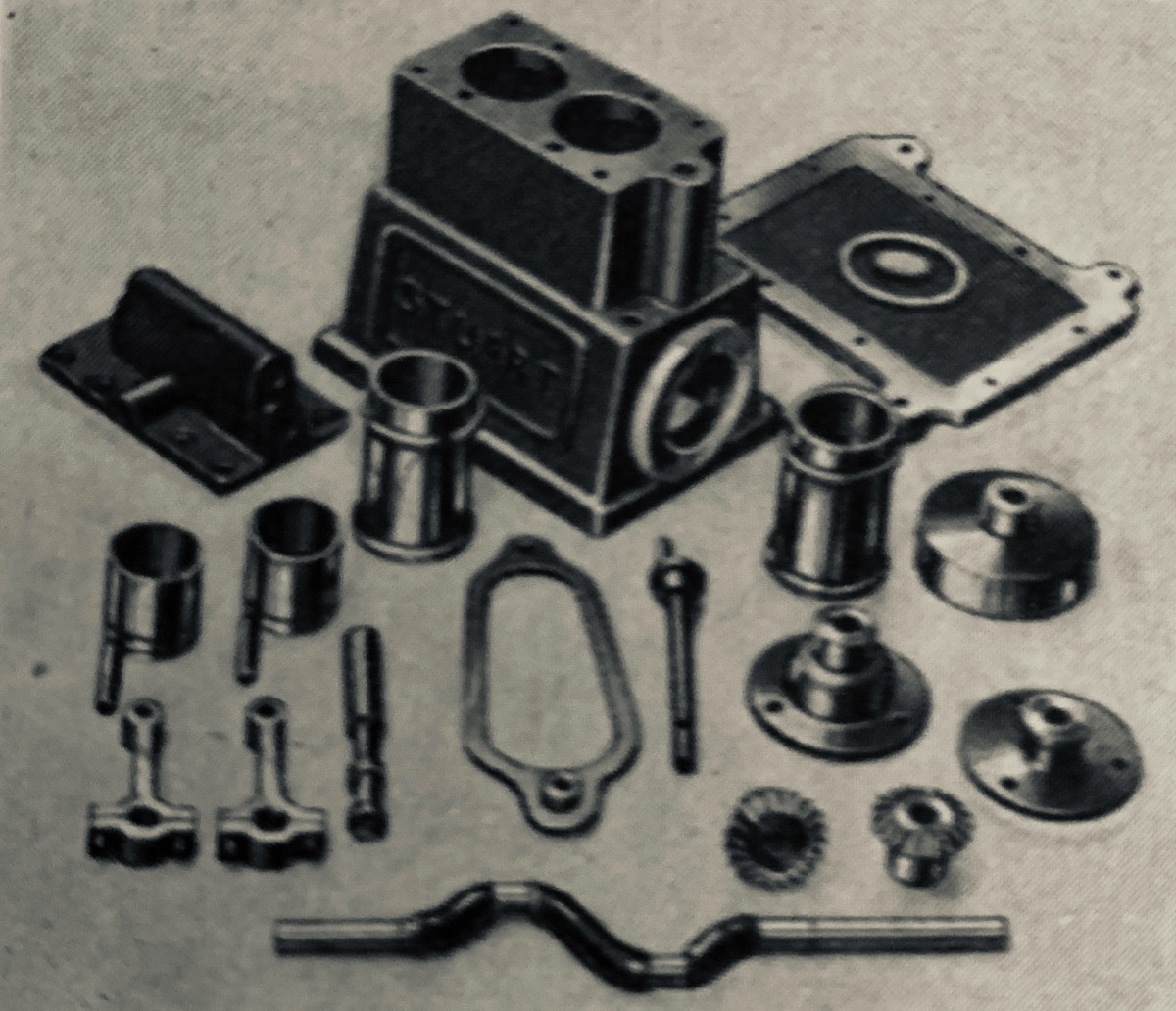

SPARE PARTS

(Post Free).

Body, 8/- ; Baseplate, 1/- ; Pistons with gudgeon pins, 3/- per pair ; Connecting Rods, 2/- per pair ; Crankshaft, 2/6 ; Gear Wheels, 2/- per pair ; Vertical Valve Shaft and Eccentric, 1/- ; Main Bearings, 1/- each ; Banjo Valve Rod, 1/- ; Piston Valve, 2/- ; Valve Chest, 4/- ; Flywheel, 1/- ; Lubricator, 5/-.

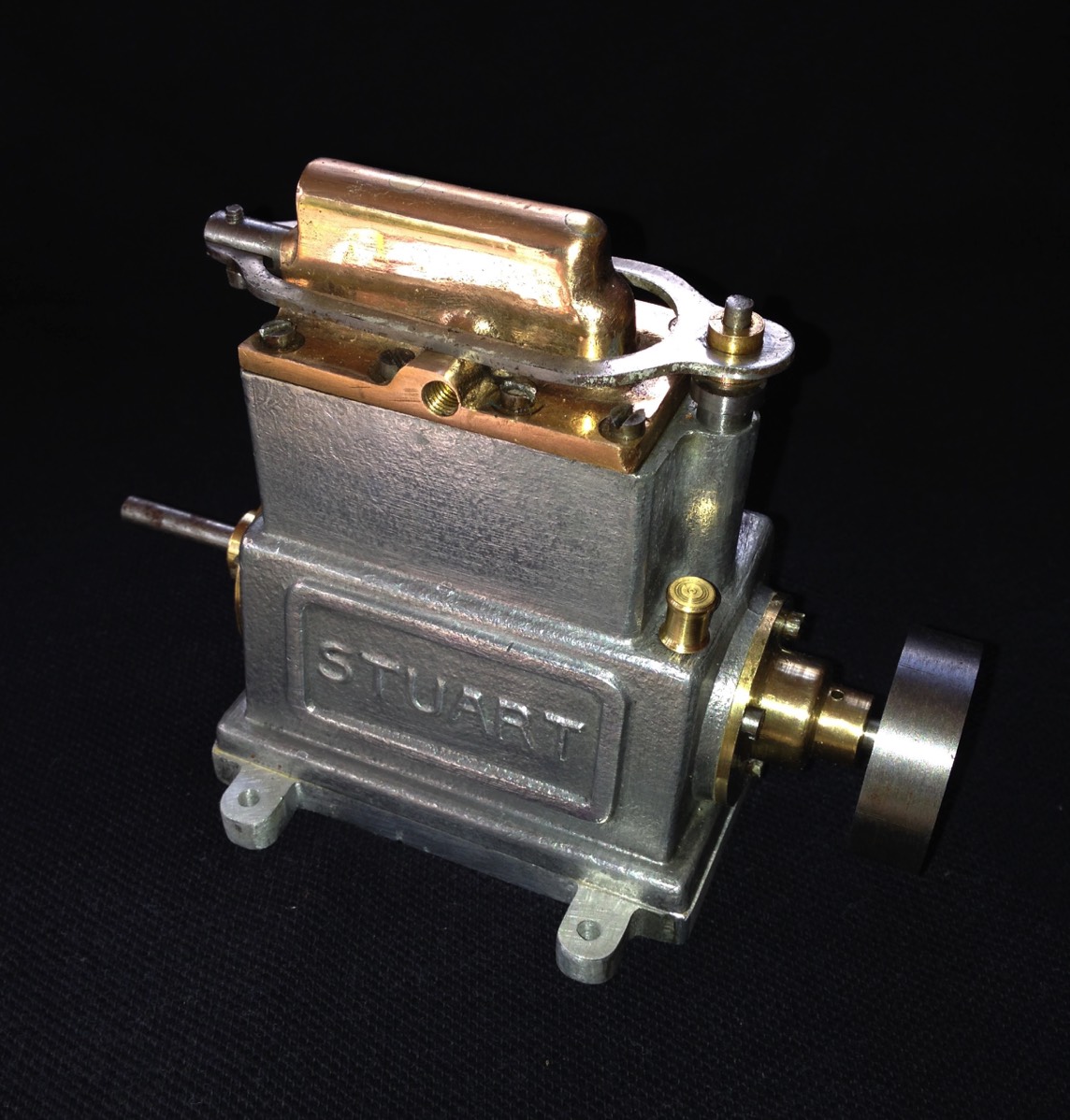

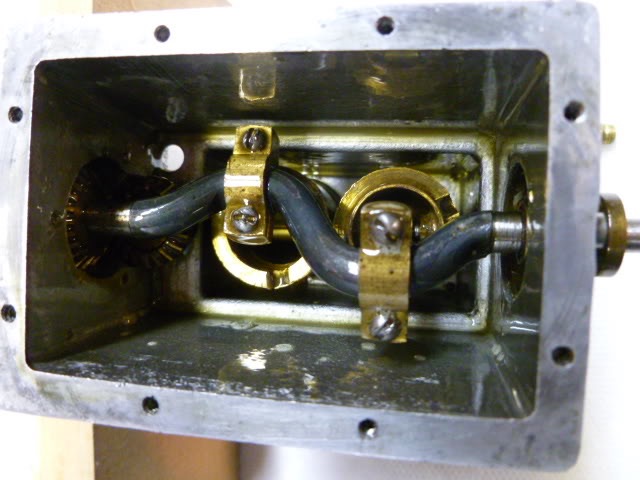

This new twin cylinder marine engine was Stuart's first standardised engine. The parts were machined with such accuracy that they were interchangable. Machined spare parts were also made available. To increase speed and reduce prices several design elemnts have been introduced. The body consists of a single main aluminium casting, a valve body and a baseplate. The main body has holes in it for the two brass cylinder liners. These are double drawn to make the brass very hard wearing. They are press fit into the main casting. Two brass bearings fit into the ends of the main casting and support the single piece bent crankshaft. This requires an absolute minimum of machining. The crankshaft is of opposing design meaning the engine is not self starting. It does however mean that the pistons are balanced reducing vibration. Short connecting rods connect to the hard double drawn brass pistons. The bevel timing gear is fitted to the crankshaft and is mounted inside the main casting, a big improvement to the previous engines with external gears open to damage and prying fingers. Another bevel gear transmits the timing to a vertical valve shaft that runs in a hole machined into the main casting. The steel shaft is running directly in the cast aluminium so care must be made to ensure this is lubricated. The top of the shaft has a small crank fitted which obscures the shaft making lubrication awkward when the engine is running. I have found engines with the casting modified to allow lubrication, common is a notch at the top edge or a hole in the side allowing direct oiling of the shaft. The steam chest is cast in bronze and has a steel piston. The piston projects from the casting, it is positioned at the opposite end to the valve shaft, The two are connected by a banjo that fits around the top of the casting. The small solid flywheel is often fitted with two drive prongs for connecting to a propellor shaft. A groove for a drive band is also found machined into the flywheel. This is a very lightweight engine that runs very fast. The engine almost purrs as the oscilating banjo adds to the visual appeal. The engine is a wet sump type which means that the bottom is filled with oil, usually to a level just below the crankshaft. The cranks then splash into the oil distributing it all over the underside of the pistons and cylinders, small grooves cut into the pistons pick up this oil and bring lubrication almost to the top of the cylinders, a displavement lubricator provides lubrication to the piston valve which is very importan as unlike a slide valve wear is not compensated for. One or Two small holes are often cut into the main casting adjacent the valve rod bulge allowing oil to be added. Oil tends to splash out of these holes when running at speed so brass plugs can be found on some engines. For the enthusiastic machinist a dip stick can be found fitted to one of the plugs. The main casting has STUART cast into the sides with a surrounding ridge. The aluminium can be quite easily be polished to a high sheen.

Stuart Henley Advert

The Henley used the Star for its power.

Please Consider Making a Donation