Stoking the steam, one engine at a time…

- © 2018 Steve Allen Contact Me 0

CONTENTS

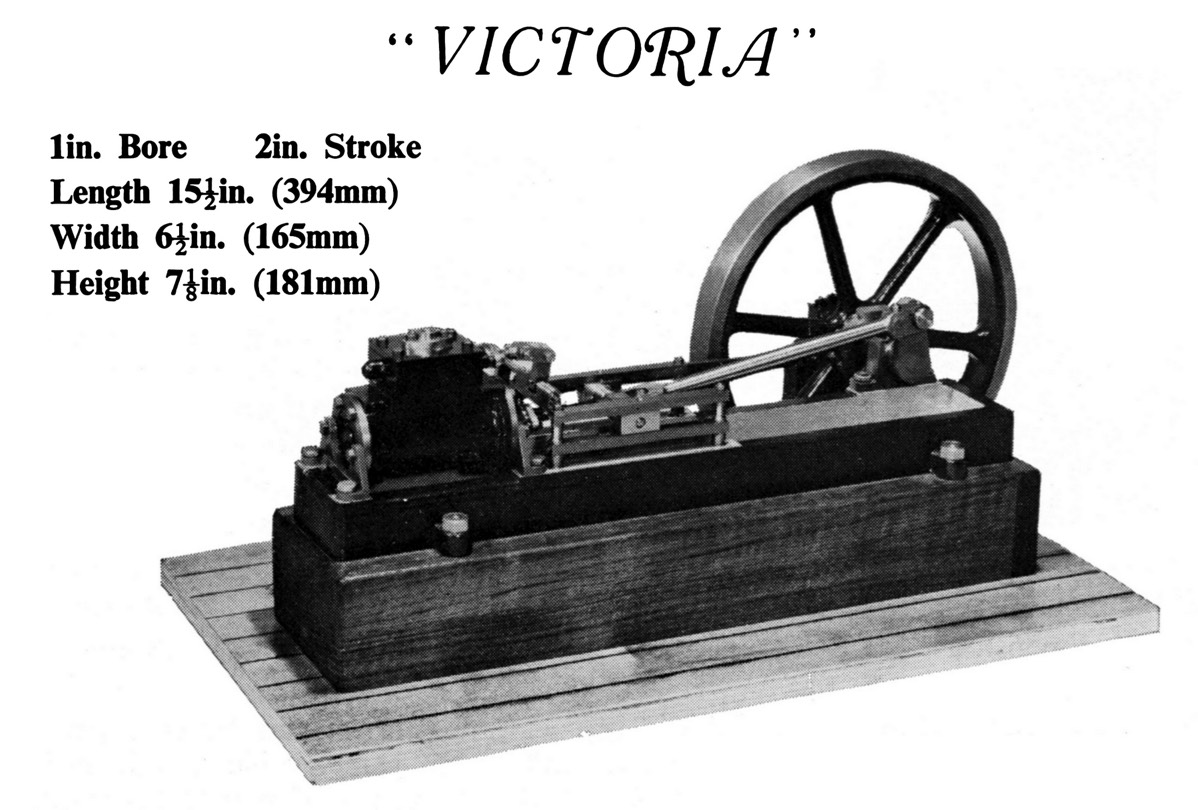

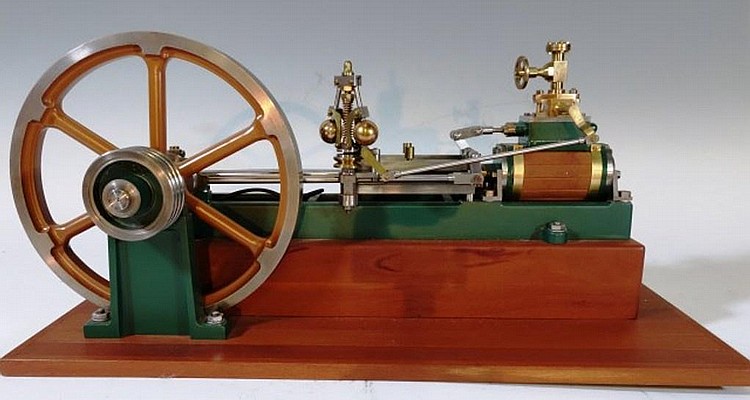

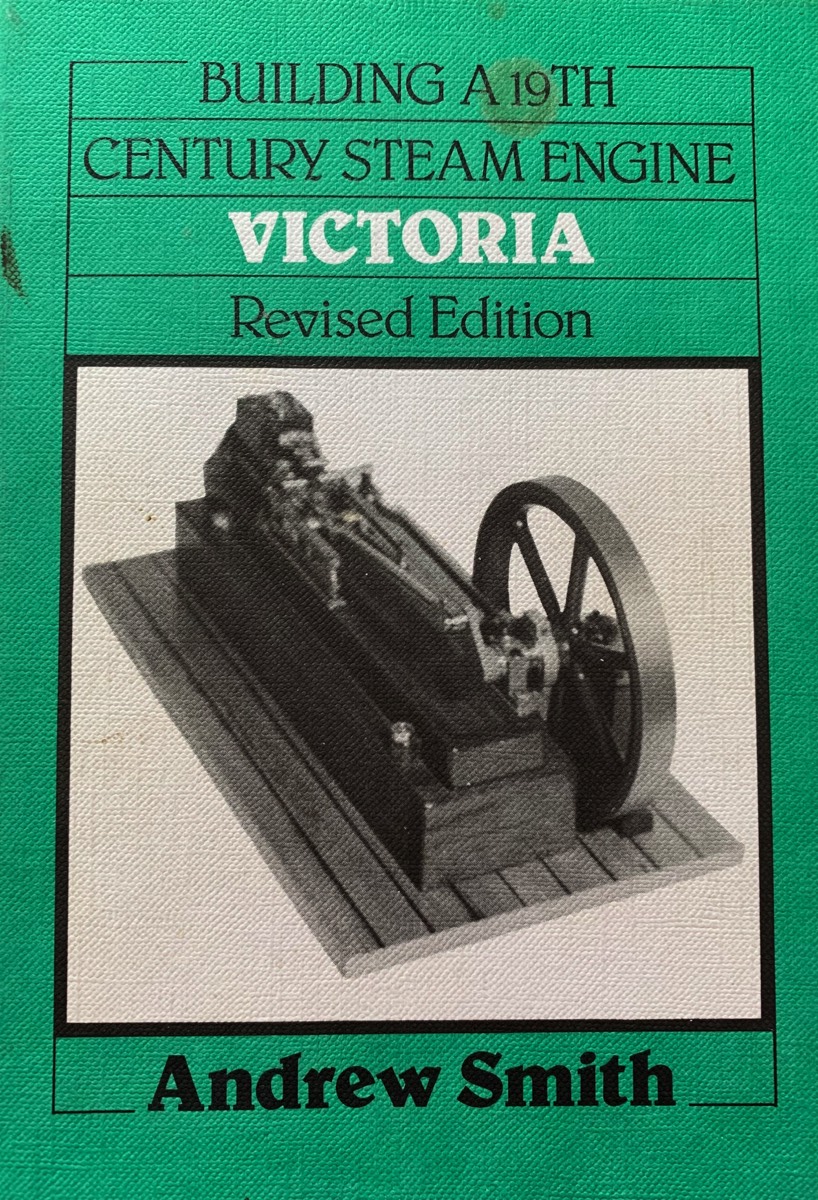

CAST IRON. Baseplate, pedestal, pulley, crank, cylinder, valve chest and cover, front and rear cylinder covers, piston, 7 in. flywheel.

BRASS. Slide valve, eccentric strap, valve operating block, glands, corned bush, crossheads, crankshaft bearings.

STEEL. Crankshaft, connecting rod, eccentric sheave, eccentric rod, clevis, crankpin, piston and valve rods, all materials for valve gear and crosshead guides.

SUNDRIES. Detailed drawings, gaskets, "O"ring, gland packing, fixings pack,

Please Consider Making a Donation