- © 2018 Steve Allen Contact Me 0

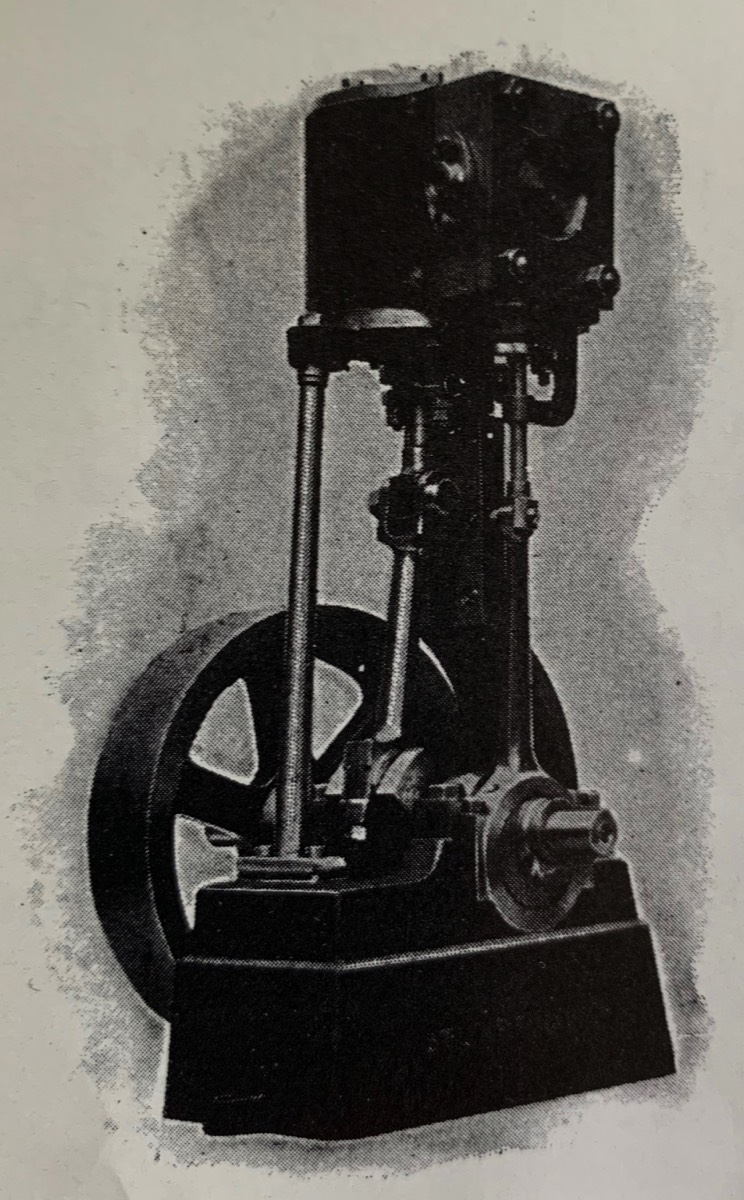

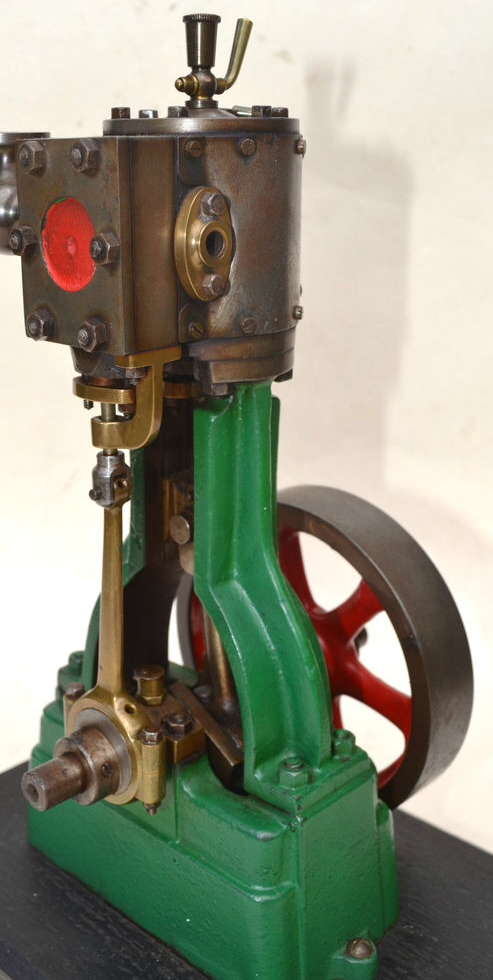

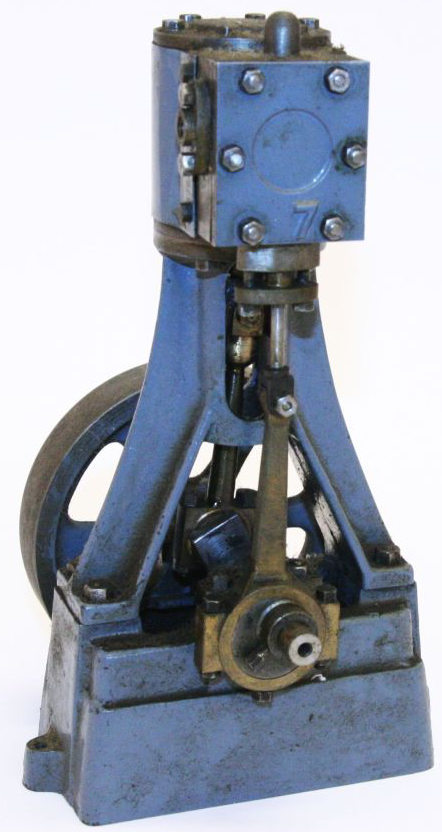

No. 7

1 in. Bore, 1 in. Stroke.

Finished Engine

£3 10s. 0d.

==========================

List of Castings

and Parts.

Price " " " 7/6. Parcel Post 9d. extra.

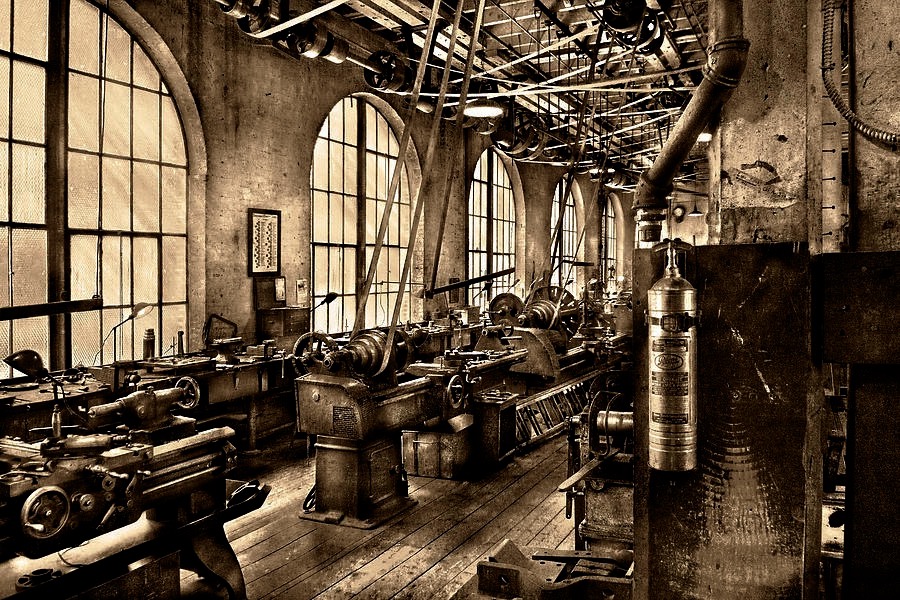

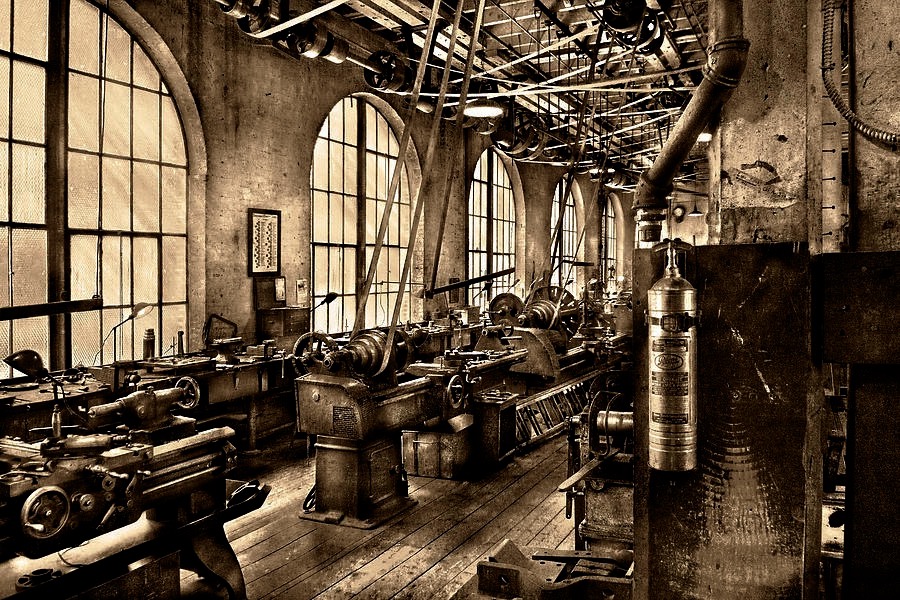

This really is a compact No.1. This reduction in size makes this engine ideal for the model engineer with limited access to machiinery, a very small lathe is ideal for machining this engine. It is also ideal for using with a smaller dynamos. It is also much less intimidating than a larger engine for the beginner. The main diferences are mainly due to the reduction in size, Starting at the bottom, the sole plate has been combined with the base as opposed the the 2 separate pieces in the No. 1. This is the main identifying point for this engine. The base is stepped like the two parts of the larger brother but has a wide rib cast in that runs from the bottom to the top where the standard and rod mount. (See front and back pictures below. Note that the catalogue image and the picture in the sidebar dont have this slope on the front of the base, the engine in the sidebar does have this slope on the back. It may be that the early versions had only a back slope but was modified for later versions) The next change is that the eccentric strap and rod are combined into a single gunmetal casting. cast with a stretched eccentric hole so that cutting the eccentric into two phalves with a 3/32 cutting disk will leave a round hole ready for easy turning. (I think I remembered the size correctly) The engine in the sidebar has no valve rod guide and relies on a long bulge on the top of the valve chest to provide a guide to the valve rod. The engine shown in the catalogue does show a separate guide. It is quite possible that the design was changed between original release and this cataloge, as did the No.1. The Valve rod guide, the Cylinder Block being so much smaller that the big brother there is no room to mount it on the block behind the rod, so it is instead mounted to the right of the rod on the Valve Chest. A single piece piston rounds off the differences. The screw pattern on the Valve Chest Cover is often used to identify between the different models but as can be seen below this small No.7 has been machined with the same pattern as the much larger No.1

In 1926 Stuart advertized the new No7a alongside the original No.7. They added the 'a' suffix to denote the change in design. On most other engines that evolved they didn't bother with this diferentiation. I have included images below of all three variations of the No.7 to show the evolution. Check out the Evolution V page for more detailed descriptions;

Please Consider Making a Donation