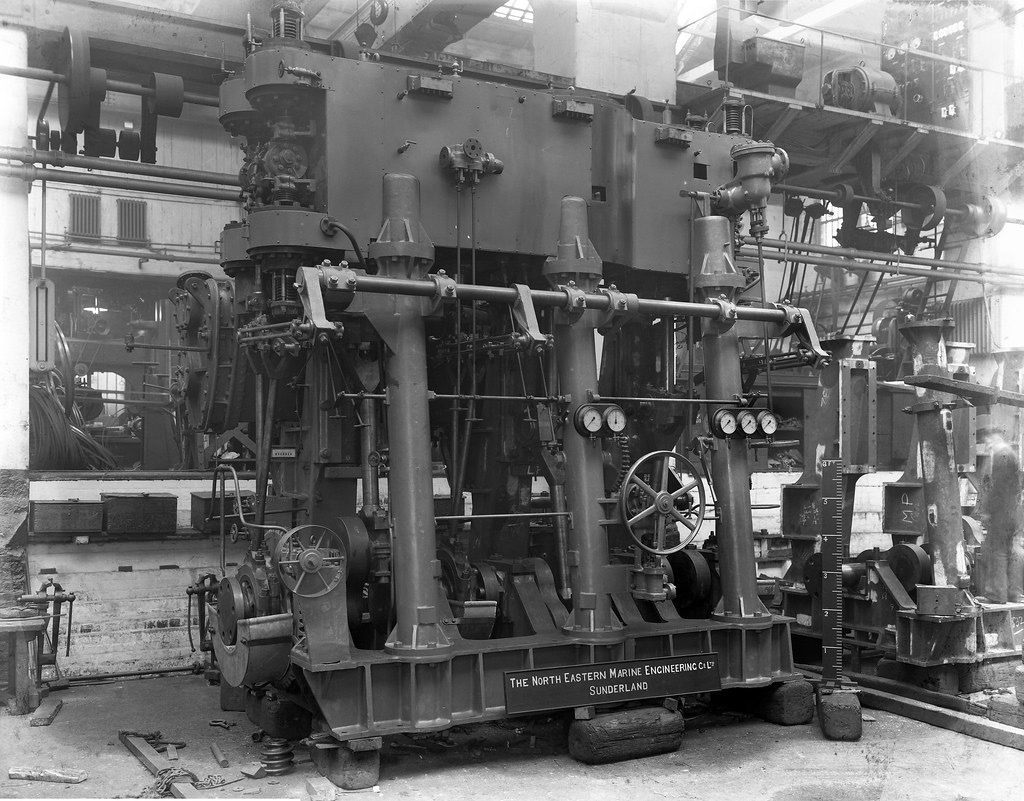

- © 2018 Steve Allen Contact Me 0

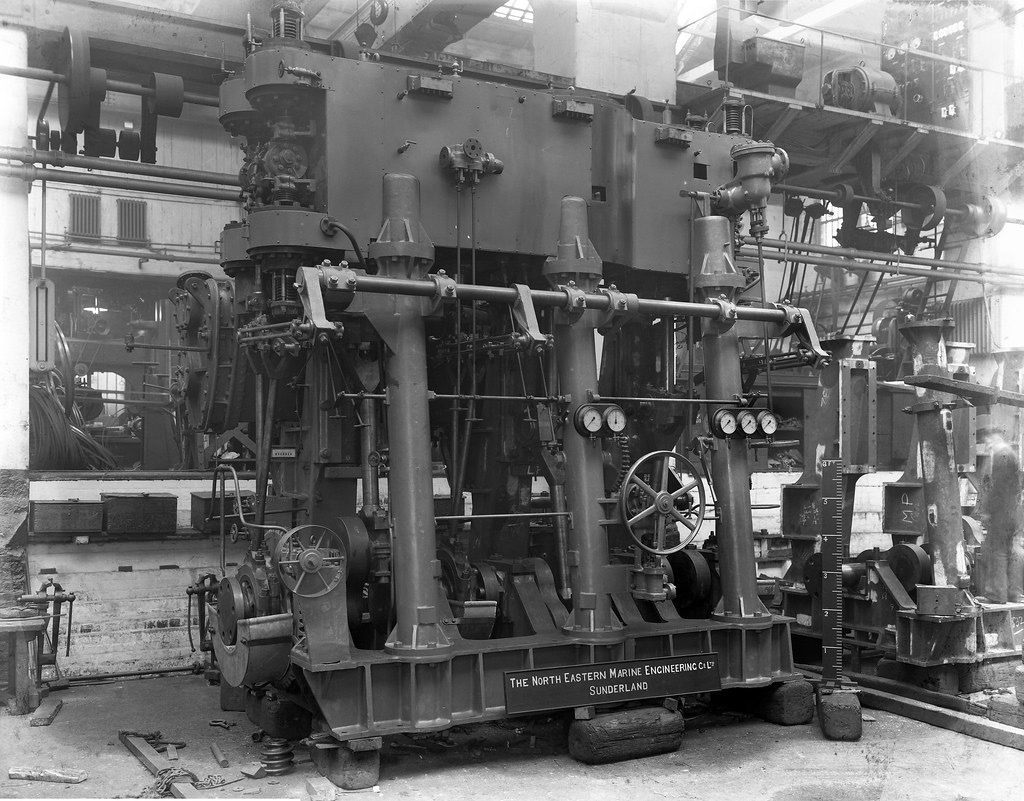

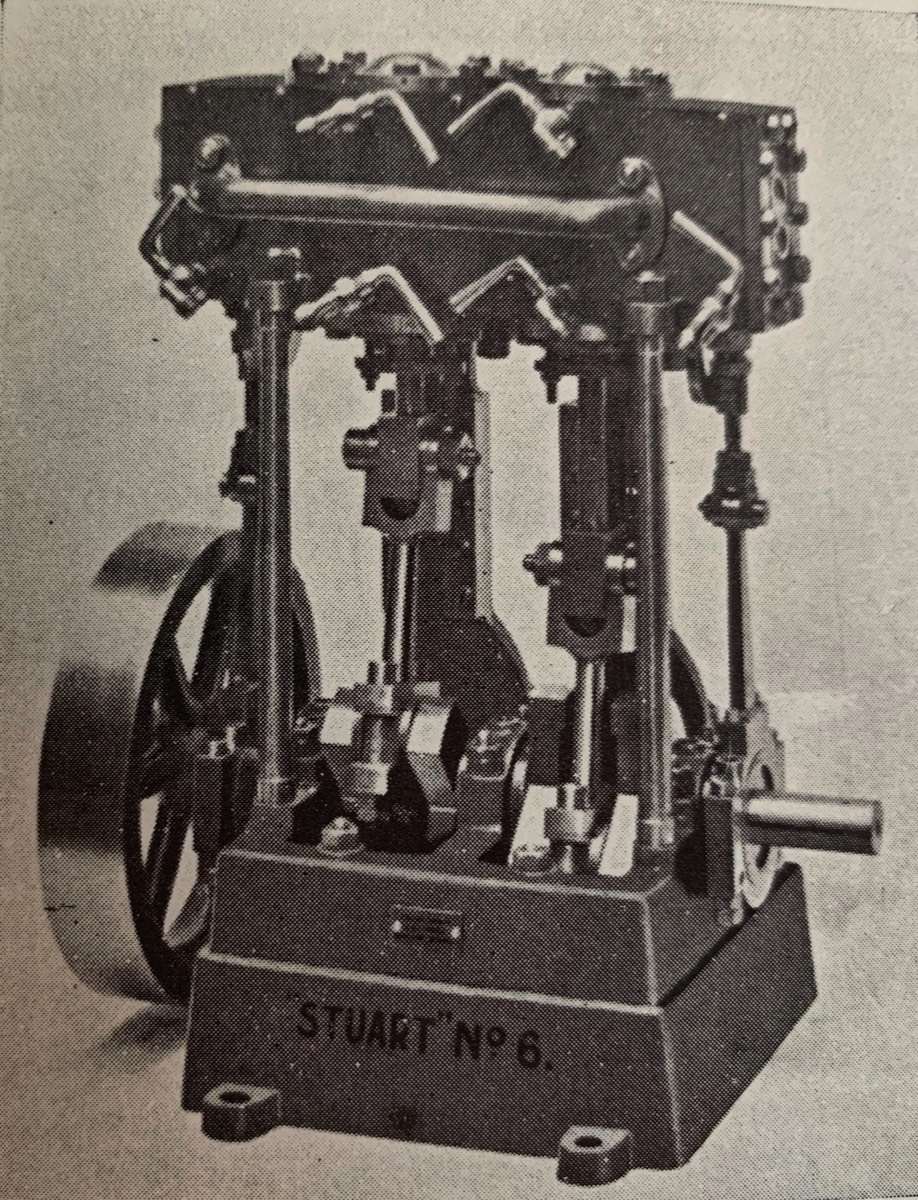

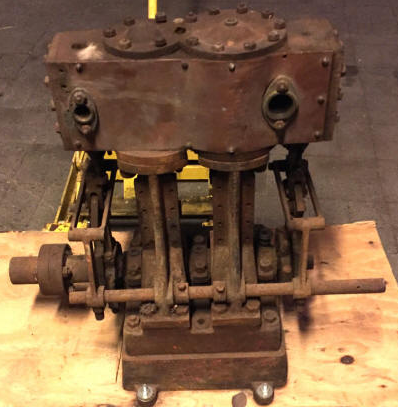

Stuart No. 6

= high speed =

Compound Engine.

Cylinders 2 1/2in. and 4in. x 3in. Stroke With Balanced Cranks.

=====================================================================

No. 6

Compound.

2 1/2in. and 4in. by 3in. Stroke

Finished Engine,

without Reversing Gear

(as shown on page 13,

Price = £25 0s. 0d.

With Reversing Gear,

Price = £33 0s. 0d.

List of Castings and Parts.

CAST IRON.-Cylinders and Valve Chests in one casting, with steam ports cast in, 2 Pistons, 2 Covers, 2 Bottoms, 2 Chest Doors, 2 Slide Valves, 2 Standards, 1 Sole Plate, 1 Box Bed, 1 8in. Disc or 10in. by 2in. wheel, 4 Counterbalance Weights, 2 Eccentric Sheaves; 2 Valve Stuffing Boxes.

Gun-Metal.- 2 Piston Glands, 2 Valve do, ; 2 Valve Rod Guides, 2 Pairs Eccentric Straps, 4 Con. Rod Brasses, 6 Main Bearing Brasses; 4 Flanges, 2 Crosshead Bushes.

Mild Cast Steel.- 2 Connecting Rods, 2 Eccentric Rods, 3 Main Bearing Caps.

Forged Steel, etc.- 1 Crank Shaft, 2 Piston Rods with Crossheads, Steel for Front Columns - Crosshead, Connecting Rod and Eccentric Strap Bolts ; 4 steel Guide Plates, 6 Finished Steel Piston Rings, CopperTube for Eduction Pipe. Steel Sheet for Lagging; 2 Bright Steel Valve Rod Heads.

A large sheet with every part fully dimensions is included.

Price, packed and Delivered, Henley Station, G.W.R. £6 0s. 0d.

=====================================================================

EXTRAS

All Studs, Bolts and Nuts, Split Pins, etc.,£1 10s. 0d. Reversing Gear Castings and Parts £1 10s. 0d. Set of Cylinder Drain Cocks with Unions and Pipes, £1 5s. 0d.

These latter have been specially made to suit this Engine since the photo on page 13 was taken.

The overall dimensions are : Height, 18in. ; Length, 14in. ; Width, 10in. exclusive of Box Bed. Weight about 150 lbs. Speed up to 750 revolutions per minute, Steam pressure 120 lbs., but extra drawing may be obtained showing Valve setting for 150 lbs.

Packing for export and delivery, London Shippers, 10/- extra.

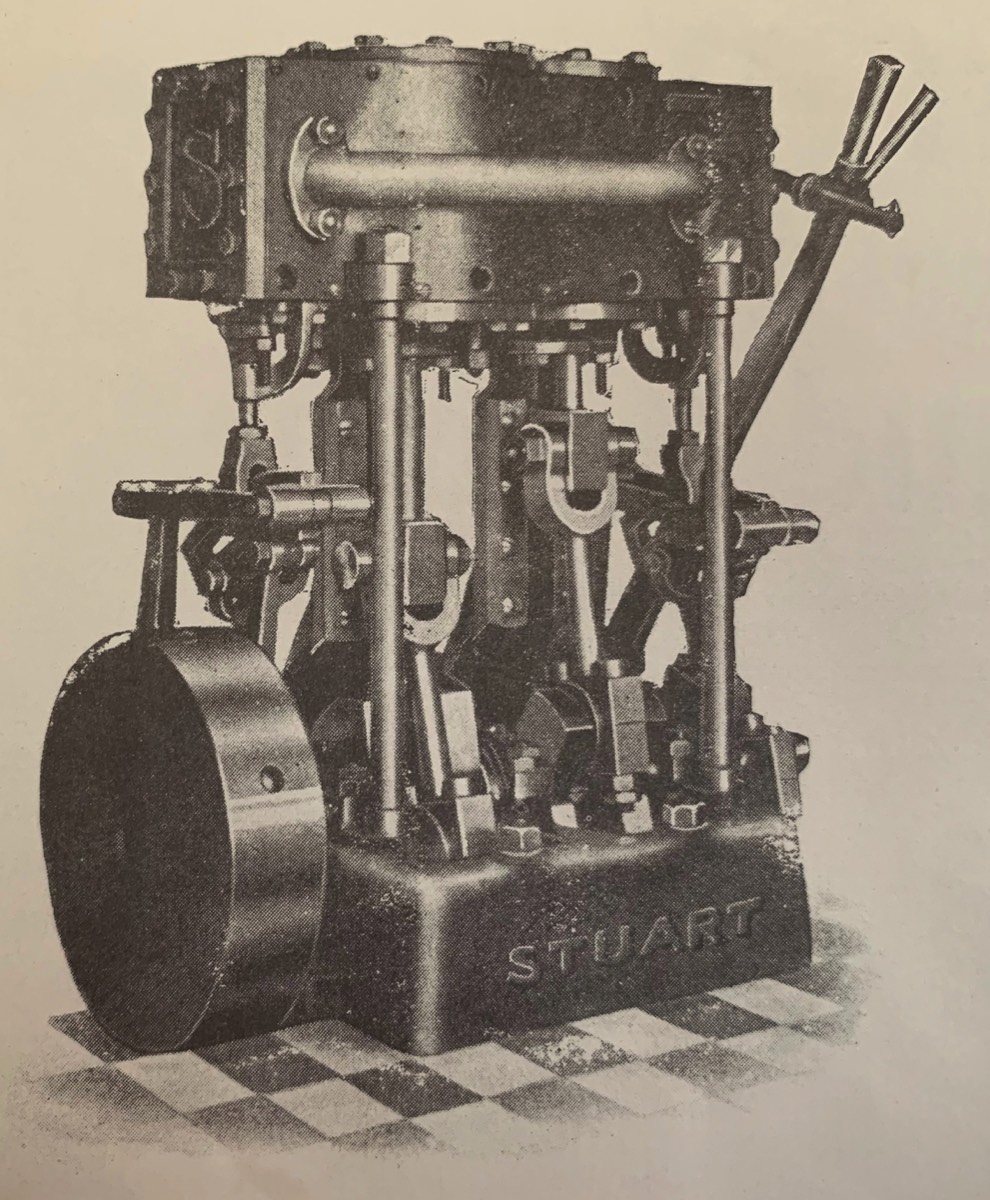

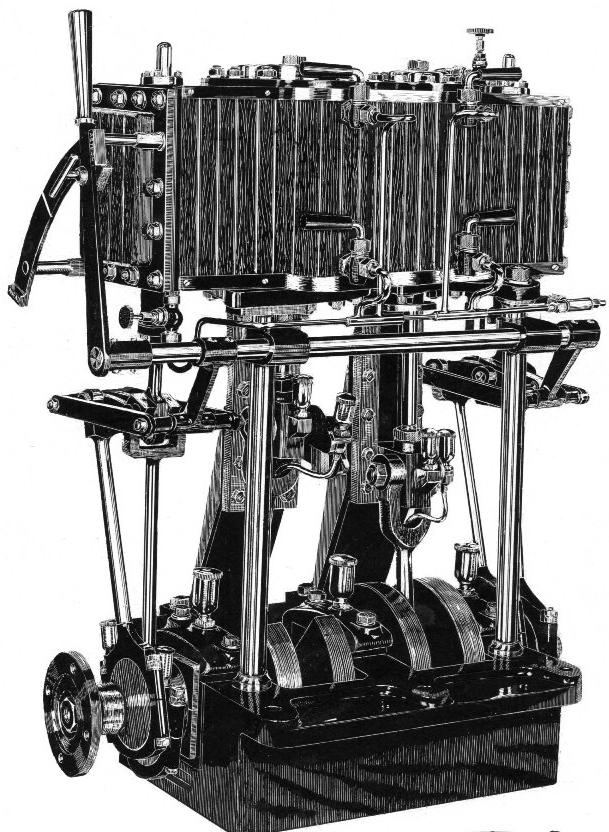

This is the next evolution of the No.3 Compound. The power of this engine is enough to propel a full size launch up to about 25' length. This made the engine very popular. A few small changes have been made to accomodate the increase in size. The most noticable are the Valve rod support brackets being mounted in front of the rods, on the front of the valve chest, instead of beside them mounted inboard of the valve chest. The reversing lever is no longer mounted on the valve chest cover moving up and down, but is now mounted to a pivot point situated at the bottom and back of the soleplate and moves backwards and forwards. Much easier to operate when sitting in ones' steam launch.

I couldnt find any video of a No.6 running. So I have included this video of a No.6a an improvement made when the engine was reintroduced in 1980.

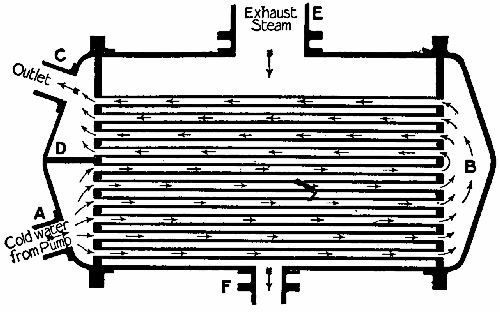

Improved piston rod glands, and inclusion of a vacuum pump to maintain a vacuum if a steam condensor is fitted to the at the low pressure exhaust. This allows fresh water recovery to increase boiler runtime. It also increases power by lowering the pressure at the low pressure cylinder exhaust. Reducing the exhaust pressure to 0 bar 15 p.s.i. below atmospheric pressure has a similar effect to increasing boiler pressure by a similar amount. The vacuum pump is connected to the low pressure cylinder crosshead and mounted behind the engine.

Please Consider Making a Donation