- © 2018 Steve Allen Contact Me 0

CONTENTS

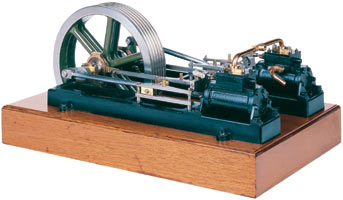

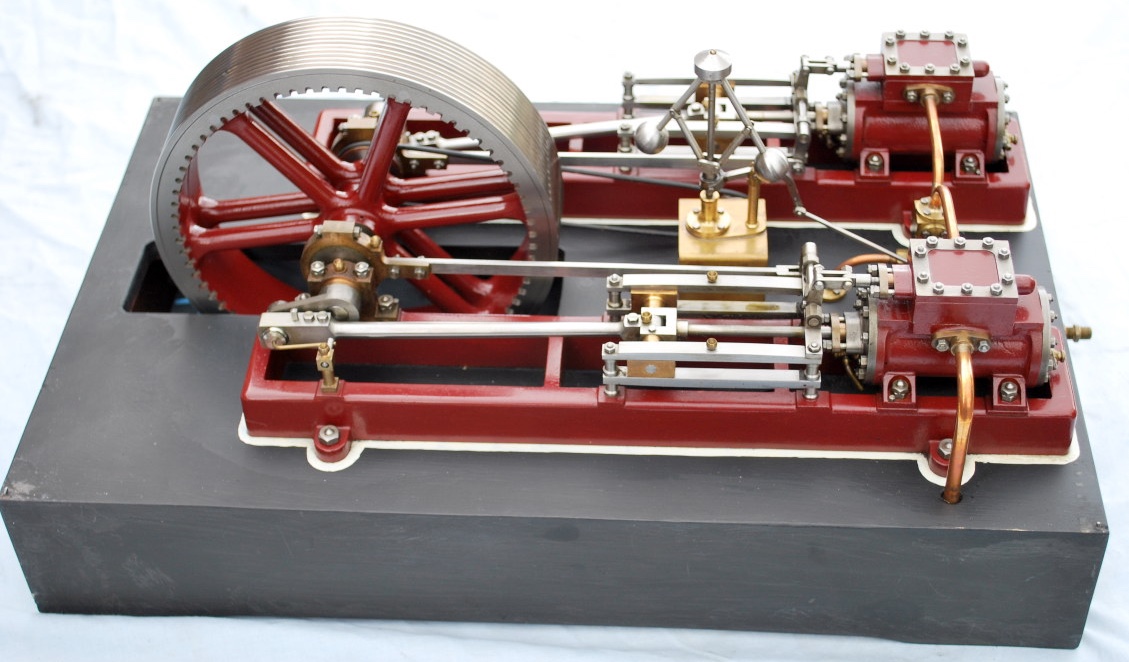

CAST IRON. Baseplate, pedestal, pulley, crank, cylinder, valve chest and cover, front and rear cylinder covers, piston, 7 in. flywheel.

BRASS. Slide valve, eccentric strap, valve operating block, glands, corned bush, crossheads, crankshaft bearings.

STEEL. Crankshaft, connecting rod, eccentric sheave, eccentric rod, clevis, crankpin, piston and valve rods, all materials for valve gear and crosshead guides.

SUNDRIES. Detailed drawings, gaskets, "O"ring, gland packing, fixings pack,

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

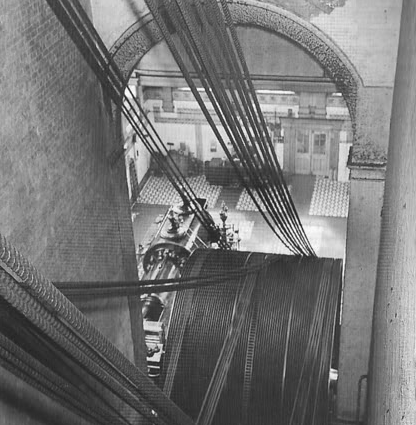

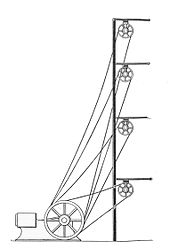

Mill Factory Rope Drive

On real mill engines the power was transferred from the on steam engine to each floor of the factory by ropes running from the flywheel machined with as many as 40 rope grooves to pulleys for each floor, power was then transferred to overhead shaft drives and pulleys to each machine. Ropes were used as they were much more effective than belts. Belts slip more than ropes which run in V grooves. Multiple ropes were used to connect each pulley to the main flywheel so that if one broke work could continue uninterrupted until the next scheduled maintainance period.

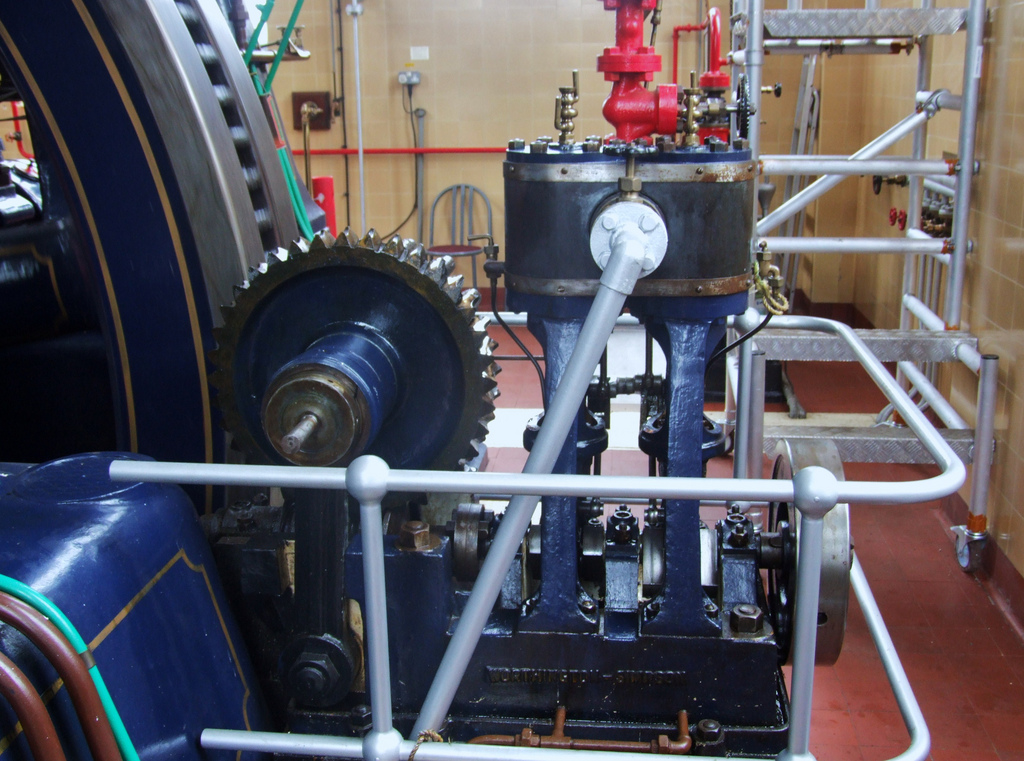

Barring Engine

A Barring engine is used to turn a large engine into its starting position.

Please Consider Making a Donation