- © 2018 Steve Allen Contact Me 0

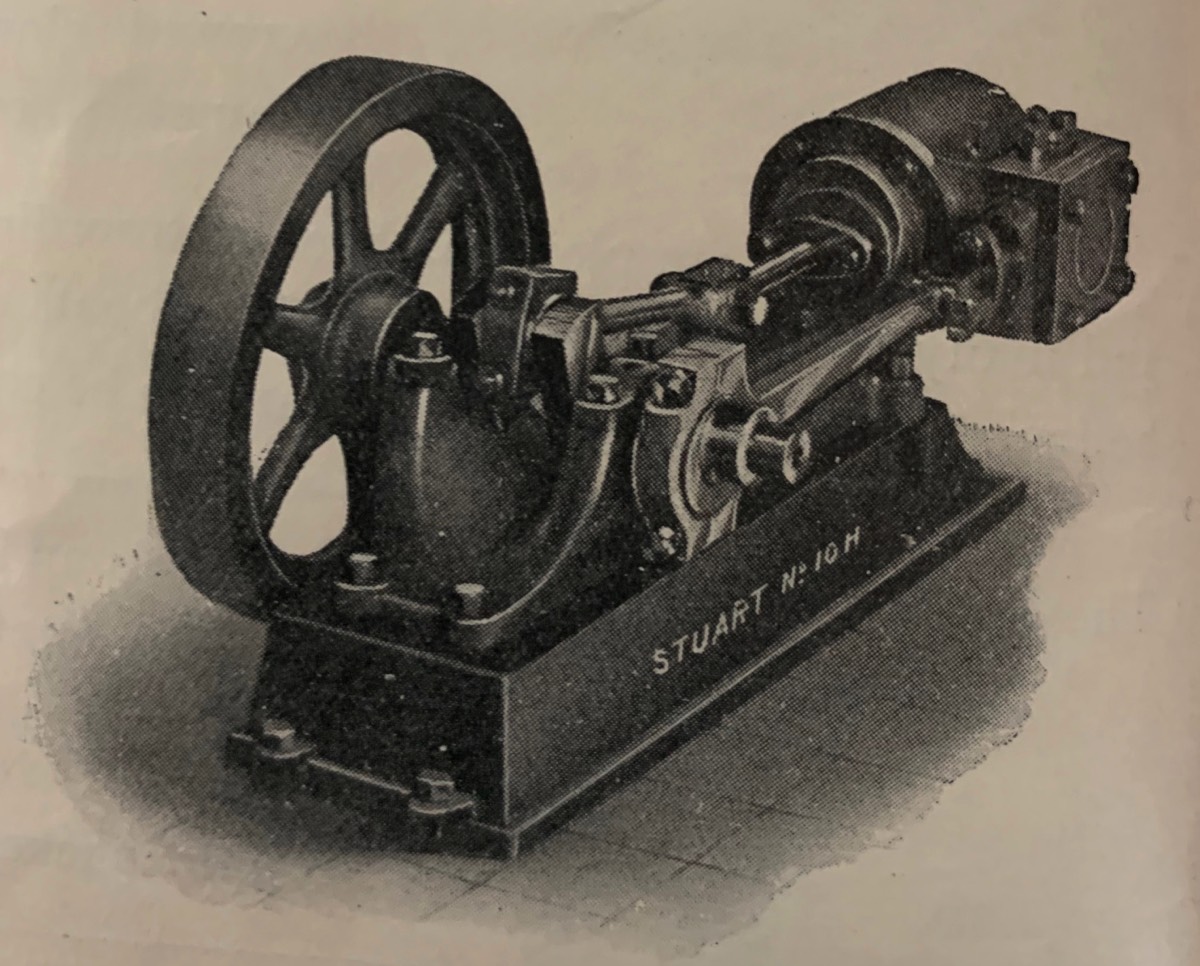

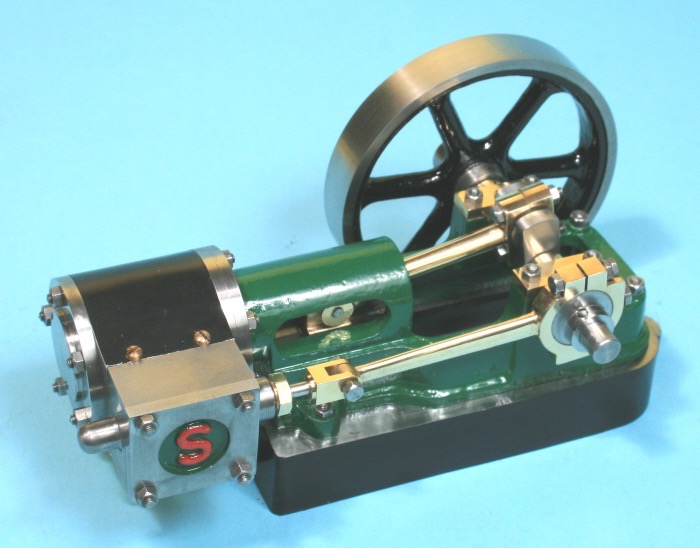

STUART No.10.

3/4 in. Bore x 3/4 in. Stroke.

VERTICAL or HORIZONTAL.

Reversing Gear not supplied.

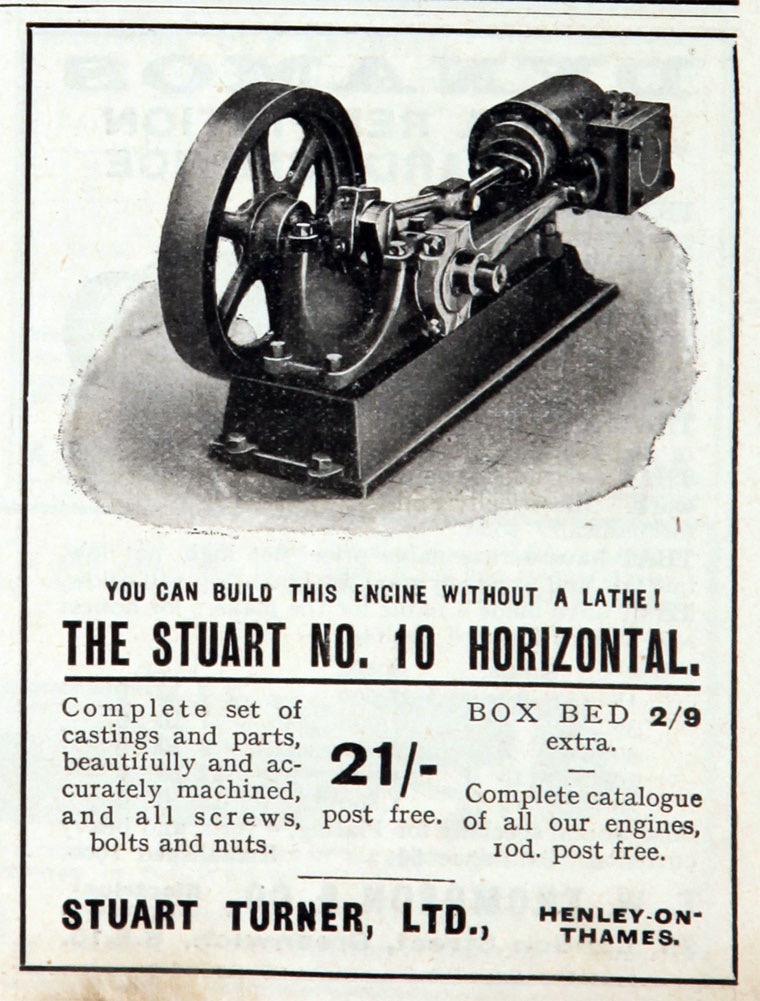

You can build these Engines WITHOUT a LATHE.

PRICES.

SET A. A hand drill and a few taps and files are the only tools necessary to build the engine.

Necessary Drills (4), 2/6. Taps (2), 1/6.

SET B All holes are accurately drilled and tapped for the bolts. A spanner and screwdriver will enable the engine to be put together.

A small file is necessary for finishing and fitting.

BOX BED (as illustrated), machined and drilled, including bolts, 2/6.

FINISHED ENGINE, on box bed, built and tested under steaming our works.

ALL POST FREE. Foreign Orders should include Postage for 3-lbs.

EXTRAS.

Lubricator, 2/3. Pair of Draincocks, 4/-.

Hardened Steel Spanner , for 3/32-in. nuts, 1/-.

This is literally a miniature No.9. Almost every feature is replicated in small size. Other than the number of bolts used to secure each part the only differences are; a combined Eccentric Strap and Rod, no Valve Rod Guide. The valve chest cover has a circular recess cast in the front, originally designed to break up the plain surface, later engines had the S logo cast into it.

The No.10 H had a single evolution from the originalm single sided croshead guide to the tubular style. This allowed the engine to be set to run in either direction without excess strain. Mounting the soleplate is however trickier to mount for machining.

30th January, 1926

C. H. P. writes :—

"I have had the No.10v Engine for 5 years, and it has run on an average five nights a week, six hours a night. I am running the engine in our town on Saturday night for the Hospital, so I want it to be at its best, and show them what the Stuart No. 10 can do, and the workmanship of your parts.

20th March, 1925..

C. R. A. B. writes :—

"I received your No.10h on Wednesday, and it is an absolute beauty."

3rd June, 1925.

L. S. writes :—

" I have just finished making your No.10h. It is a topping engine, runs beautifully. I am very pleased with it."

Please Consider Making a Donation