- © 2018 Steve Allen Contact Me 0

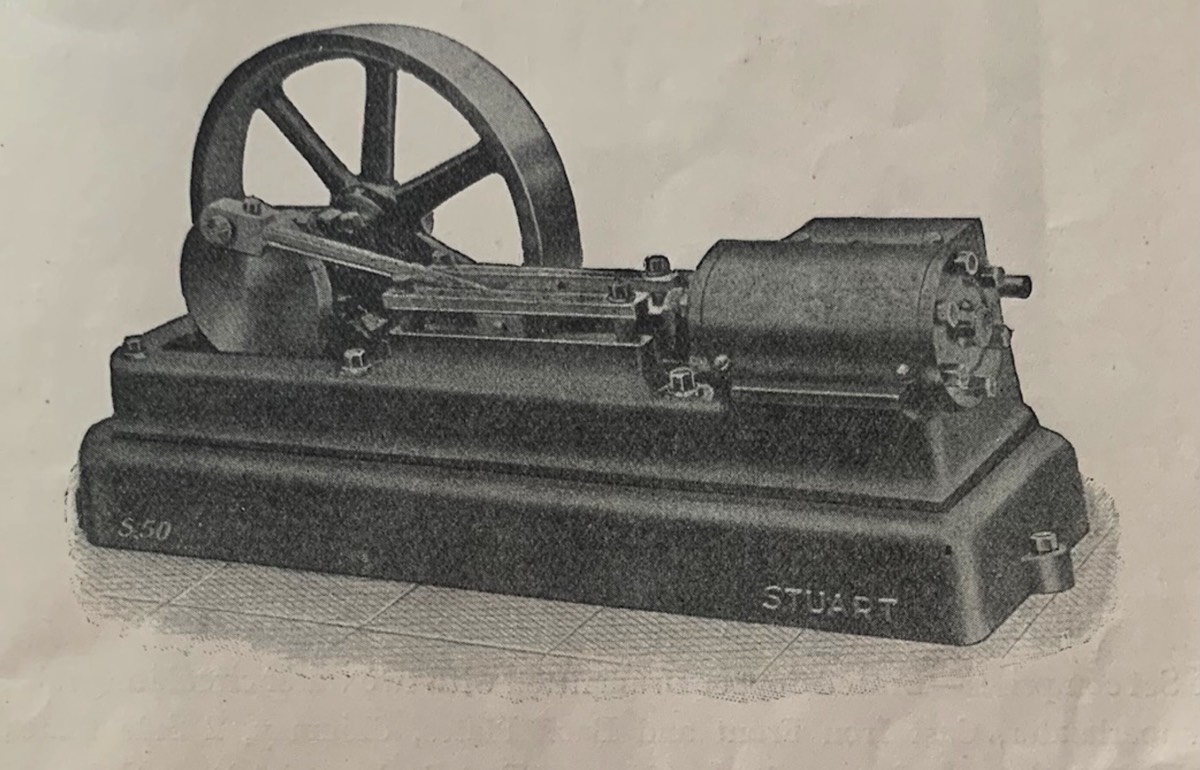

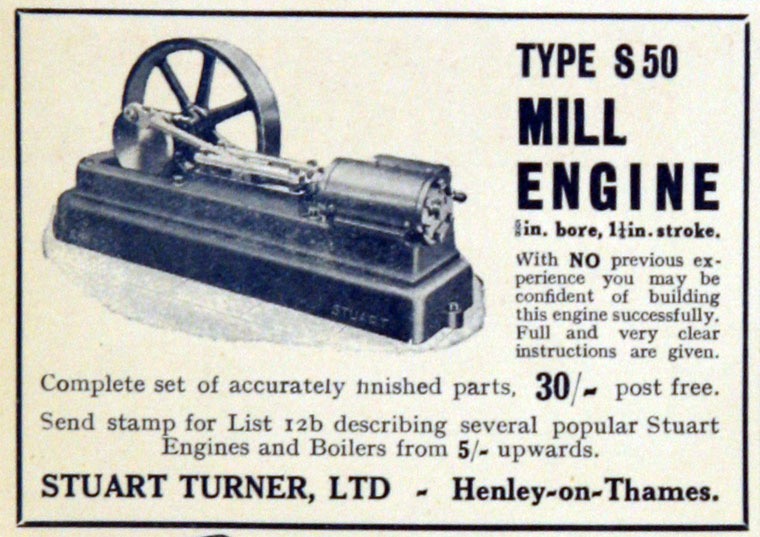

MILL ENGINE, TYPE S 50.

5/8-in. Bore, I 1/4-in. Stroke.

A perfect model engine that can be built without tools.

The Set, neatly boxed, 30/- Post free

Foreign Orders must include extra remittance for 4-lbs. postage.

Finished Engine built and tested in our works,

£2 10s. 0d. PostFree.

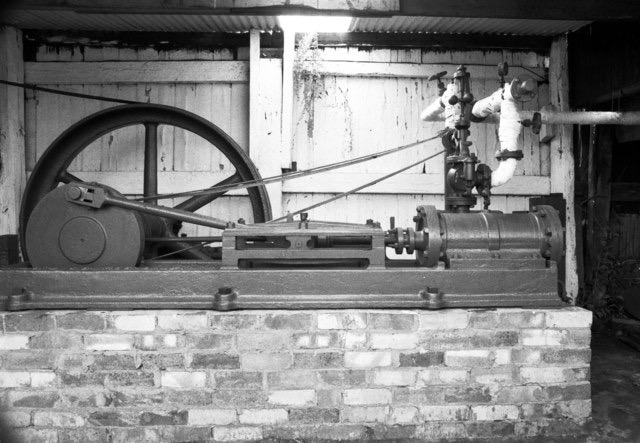

The engine I would recommend for beginners to start with. When Stuart designed this engine it is obvious that great care was taken to simplify the design. It is also clear that they didnt start from scratch, a quick glance at the Progress Horizontal Mill engine and it is clear that this was the starting point. So how were things changed? The soleplate was changed in several ways, firstly the Progress had a cut out for the large flywheel to hang between, seperate brass bearings supported the crank shaft on each side of the flywheel. The S 50 no longer has a cutout and the flywheel hangs over the side of the soleplate, the bearings are now cast in and so only require drilling and reaming, saving many bearing brass construction steps. The new soleplate has been extended to include a baseplate so there is clearance for the flywheel where on the progress mounting onto your own base was required for clearance. The flywheel was changed from an 8 spoke model to the common 6 spoke design. The crank disk that on the Progress hung over the soleplate edge now runs in a trough cast into the soleplate. The crosshead guides remain the same as does the cylinder mounting The original design of the valve chest cover was changed for the S 50. The soleplate has been extended to include a base, fake mountinf bolts are cast in to look like they are seperate. The two bearings fro the crank shaft are entirely cast in thus only requiringdrilling and reaming, this save a lot of time and effort over engineering seperate bearing brasses. The crank shaft uses a disk for simplicity instead of having to create a crankshaft with crankwebs, a massive simplification. The original engines used a full circular crankdisk, later engines have two sides cut off to create a counterbalance that resembles a triangular shape. The connrod is pretty standard with a taper towards the little end. The crosshead runs in guides that consist of 2 raised cast bars with top bar guides supported at each end with spaced studs. The raised whilst normally being milled could in fact be filed to tolerance, more simplification. The cylinder was originally cast in bronze but was later changed to cast iron, probably to allow for higher steam temperatures of improved boilers. The cylinder is mounted to the soleplate, by three studs on a flat machined, or filed onto the side of the cylinder. Brass cladding for the cylinder looks good. The valve chest and cover appear pretty standard with a long extension machined to guide the end of the valve rod, required as no external is used. A standard eccentric & strap are used with a slim rod conneting to the valve rod clevis. So if you are after a nice simple engine to machine as a first go this is probably the one.

Please Consider Making a Donation