- © 2018 Steve Allen Contact Me 0

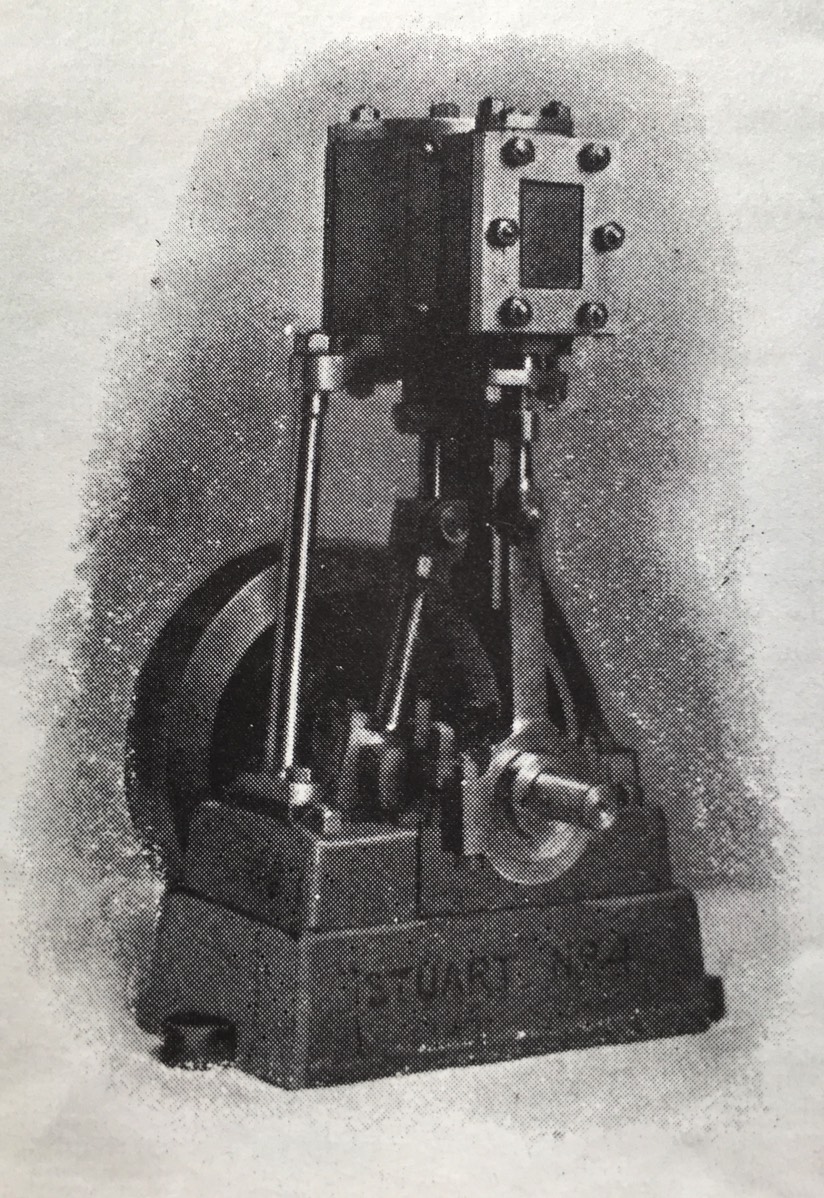

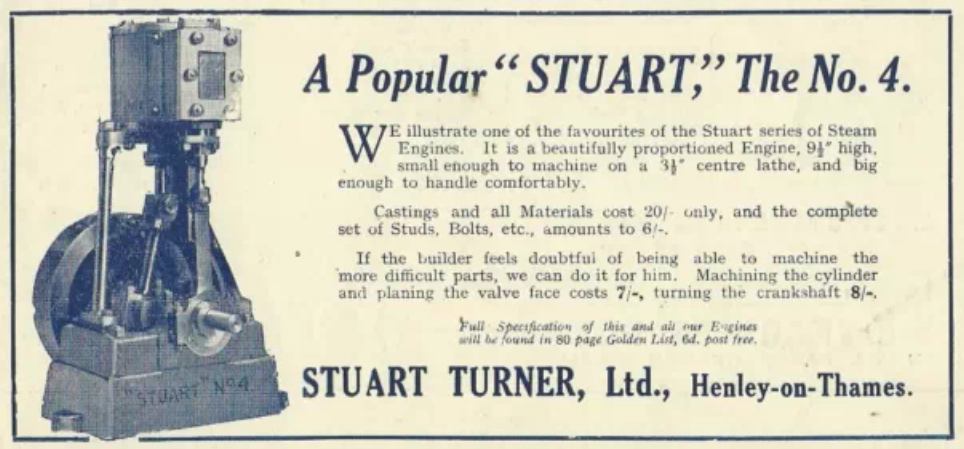

No.4

1 1/2 in. Bore, 1 1/4 in. Stroke

Finished Engines

£5 10s. 0d.

List of Castings and Parts.

CAST IRON.- Cylinder with steam ports cast in, 2 covers, piston, valve chest and cover, standard, sole plate, box-bed, eccentric sheave, balanced disc, or fly-wheel (optional)

PHOSPHOR BRONZE.- Connecting rod and cap. eccentric rod and straps.

GUN METAL.-Piston gland, valve gland, slide valve, valve rod guide, main bearing brasses and caps, steam and exhaust flanges.

CAST STEEL.-Crank shaft, piston rod and cross head, front column.

MILD STEEL.-2 Guide plates, valve spindle, steel for valve spindle-head and cross-head bolt, sheet steel for lagging.

WORKING DRAWINGS.- A fully dimensioned full sized drawing is supplied with each set.

Price, packed in strong box = = = 12/6

⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯ ⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯

EXTRAS.

Complete set of Steel Studs, Bolts and Nuts. Price 6/-

Cylinder Drain Cocks, 2/9 per pair. Single Cock Lubricator, 1/9.

This engine is an exact reproduction of the No.1 Stuart, except that it has a balanced disc in place of flywheel, and is capable of very high speed. The connecting rod is of phosphor bronze, top half of brass being cast to rod. The eccentric rod is also cast to straps, and is of same metal ; this will be found convenient in erecting, and is also very neat and strong.

⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯ ⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯

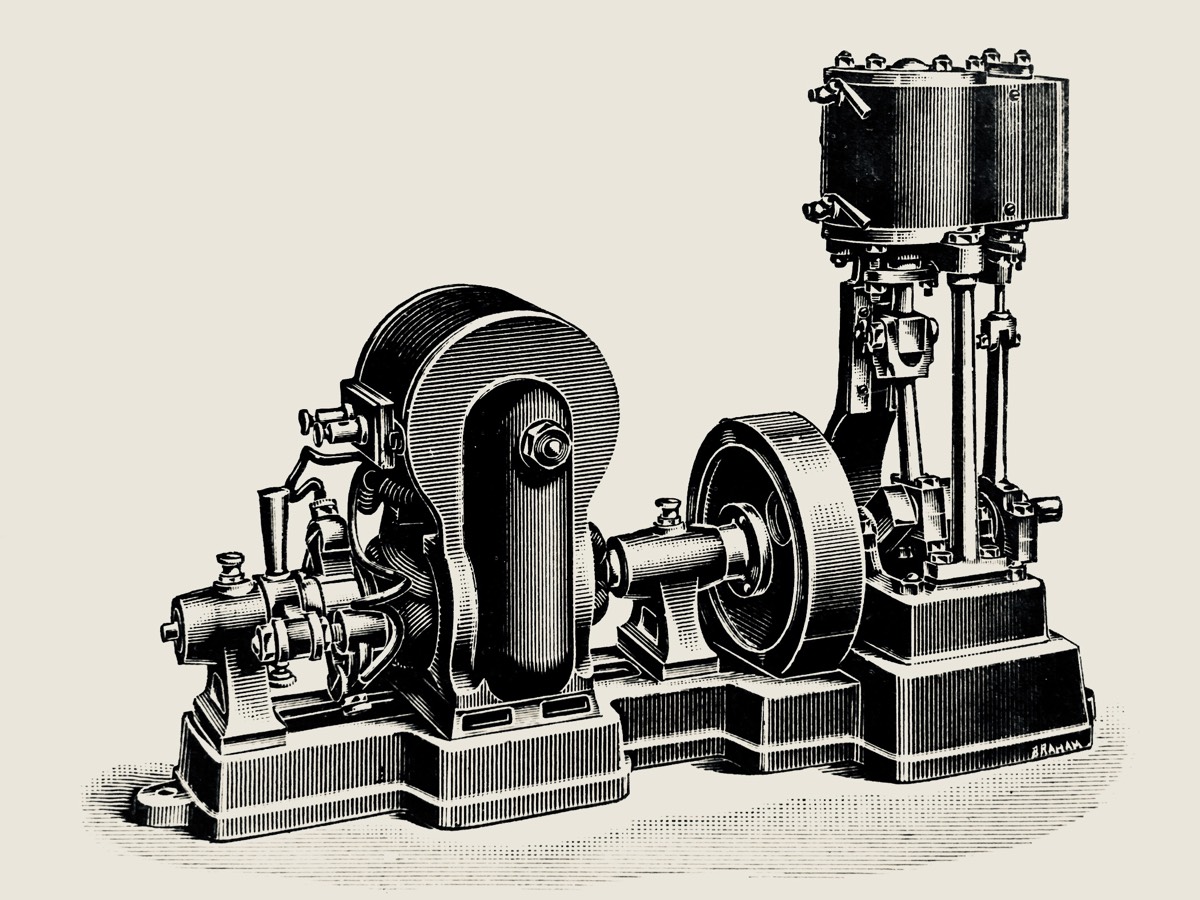

The No.2 engine whilst ideal for running a dynamo does require quite a lot of steam, from a large boiler. A more conservative engine capable of working from a smaller boiler would be useful for Customers. Hence the No.4. a smaller version of the No.2.

The design is essentially just a scaled down No.2 supplied with a disc-wheel. Also noteworthy is the lack of a reversing mechanism, the first for a Stuart engine.

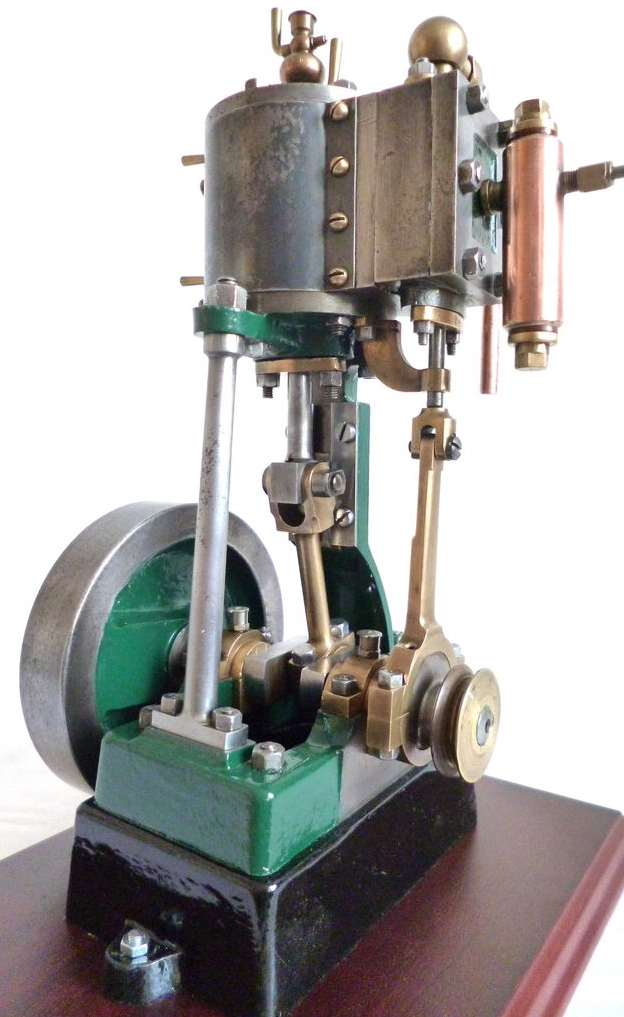

Close inspection of the catalogue image and parts description shows a change to the Valve chest. The top side has a cast in lozenge shaped mating surface for the steam inlet fitting. The two securing bolts can be seen in the photo although no steam pipe is attached. This design feature has caused a bit of controversy as to its nature. Some engines are constructed differently, with a turned fitting for supporting the end of the valve rod. Whilst this system works it is not the original intent as can be confirmed by the presence of the valve rod support bracket mounted under the steam chest and described in the parts description. Although not used in this design, the turned upper valve rod guide will turn up in some other Stuart designs.

Worthy of mention is my Early No.4, it lacks the valve rod guide and also features a different valve adjustment design. Instead of the usual threaded nut that fits in the valve guide slots, a valve bar locks onto flats machined in the sides of the valve rod. Adjustment is instead made at the other end of the valve rod, outside the steam chest where the valve rod is threaded into a longer valve rod clevis with a locking nut. This fits onto the standard combined eccentric strap/rod. This design is simpler to machine than the current design valve rod with only two flats and a threaded end compared to the two threads and turning down the supported end. This lack of support for the valve rod is the same as described for the first No.1 engines. It may be that they used the same adjustment design.

Reducing the dimensions of a steam engine is not without its dangers, reduced size results in a substantial reduction in strength and a particularly fragile part of this design is the neck of the Standard. I have seen four of these engines that have had the neck broken, something that is particularly difficult to fix due to the small cross section of the Standards neck.

Stuart Upgraded the design of several of its engines, for the No.4 they changed the Standard & Rod to an Inverted Y Trunk standard as seen below.

Please Consider Making a Donation