- © 2018 Steve Allen Contact Me 0

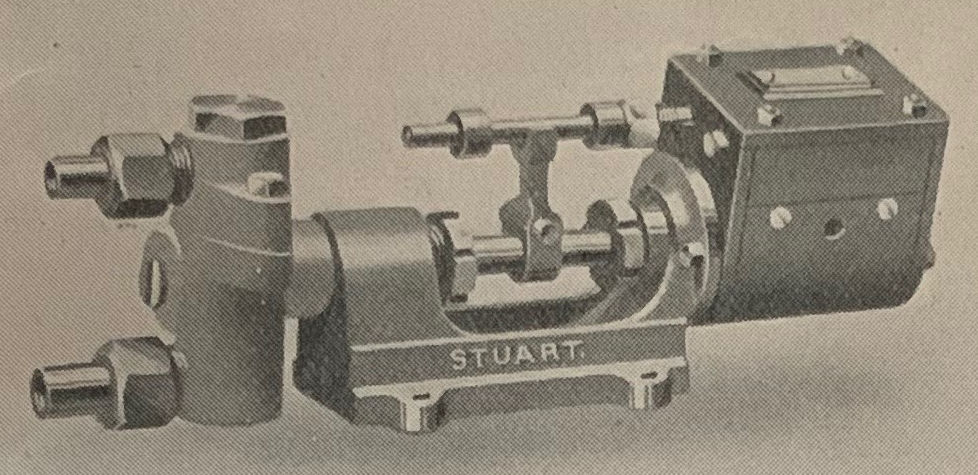

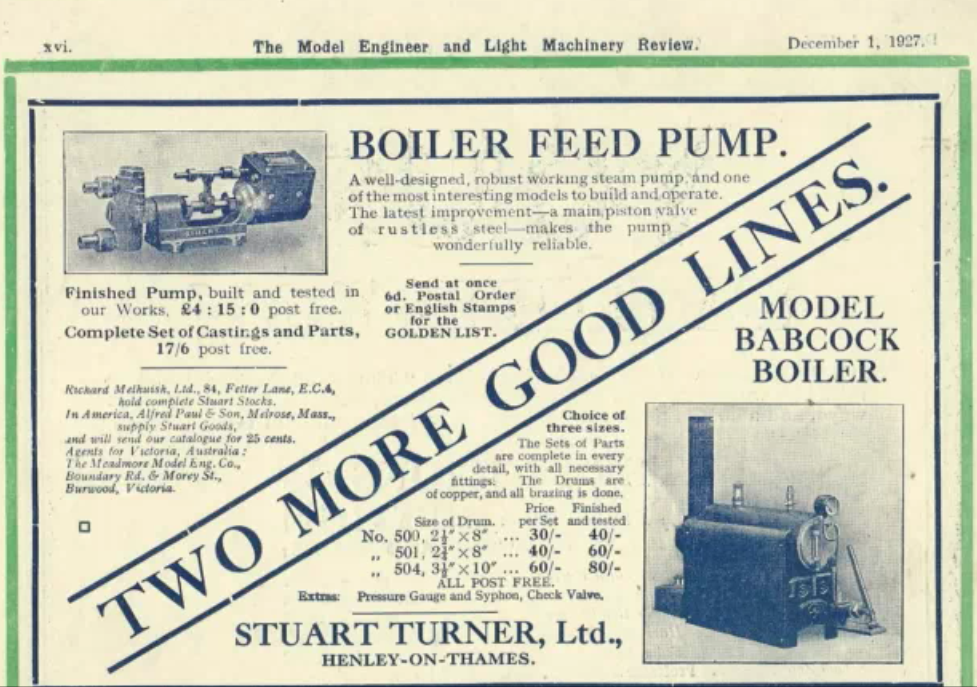

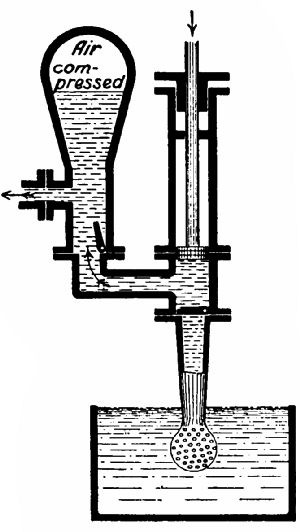

STUART BOILER FEED PUMP.

A most Effective

and Reliable

Working Model.

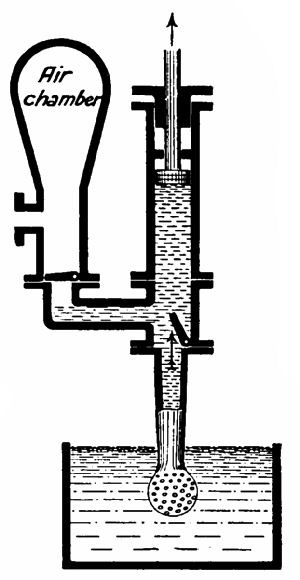

This is an ineresting design with the piston rod doubling up as the pump piston. The valve rod is moved by a bracket bounted to the piston rod so that as the piston moves to one end of its travel the bracket hits a stop on the valve rod switching the valve. This is reversed at the other end of the piston travel. It would not be enough to run a steam valve as in a normal engine where the valve is progressively opened and closed as the engine cycles. With such a short stroke and a pump requiring maximum steam pressure we need the valve to open fully as soon as it is tripped, this a shuttle valve is used. The valve gear being tripped by the piston stroke reaching the end of travel releases a small amount of steam into the shuttle valve which immediatly opens the main steam inlet providing full pressure to the piston. As soon as the valve is tripped at the other end of travel the shuttle valve repeats the process. As can be seen from the picture the valve rod (top rod) has an adjustable limit screw, and the two valve trip adjusters. A long gland nut adjustment thread also allows for careful adjustment of the valve rod resistance. This engine requires a level of accurate adjustment to run smoothly. Mounting the steam valve drectly to the valve chest is also important to minimise condesate build up that can restict the small diameter shuttle valve passageways. Drain cocks and cylinder insulation are also fitted to aid quick cylinder warm up. I have seen a few of these and most dont run well.

Please Consider Making a Donation