- © 2018 Steve Allen Contact Me 0

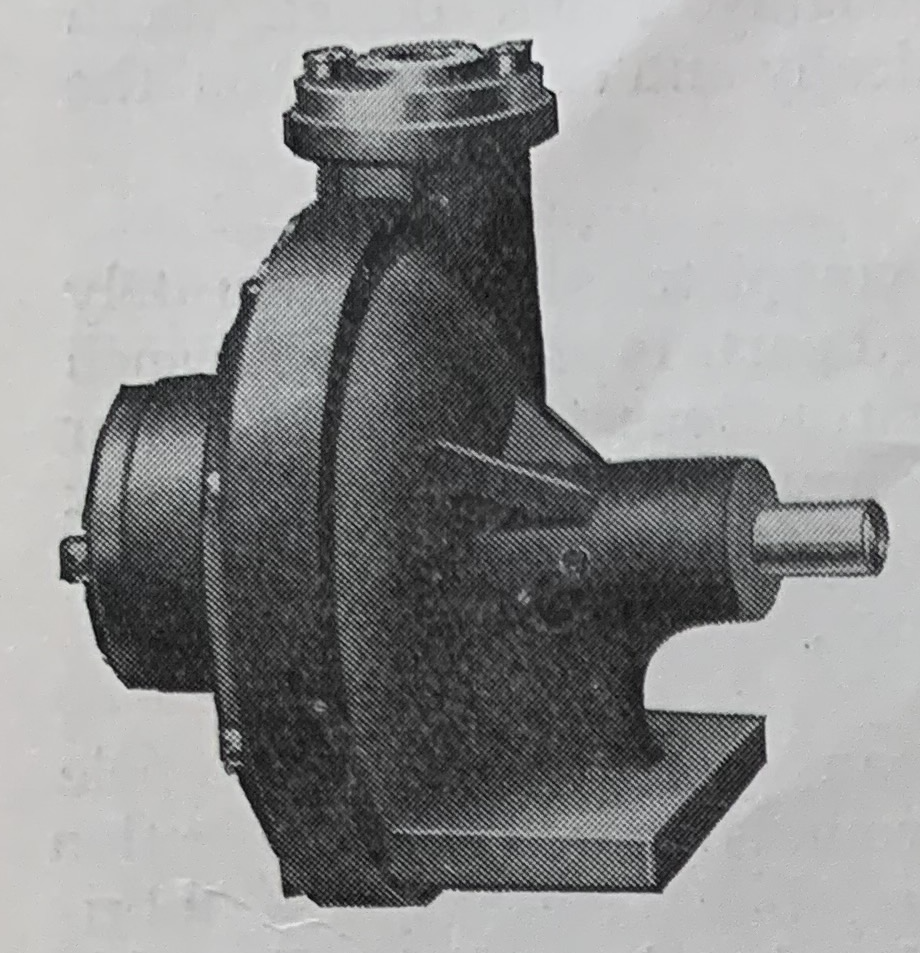

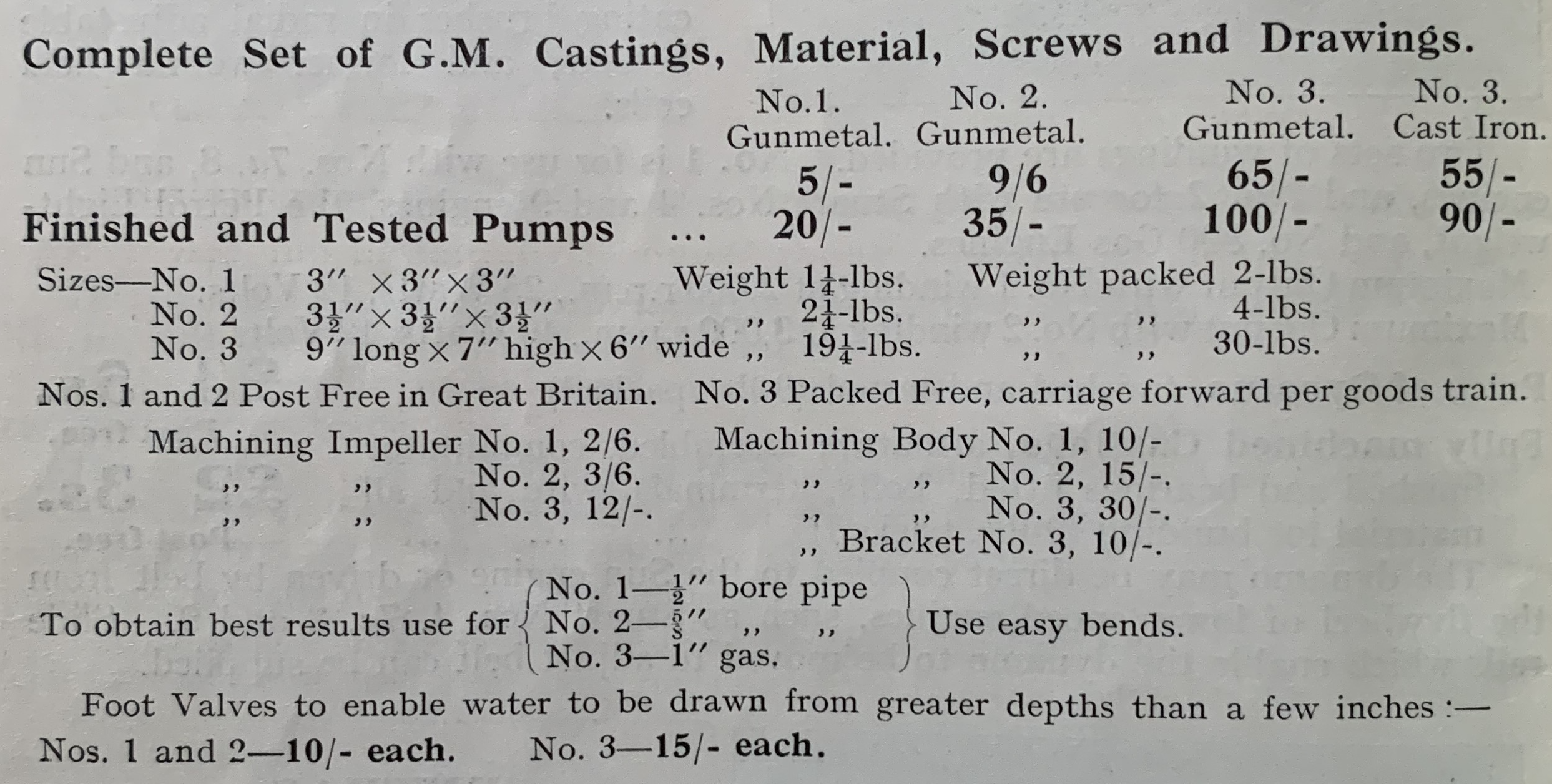

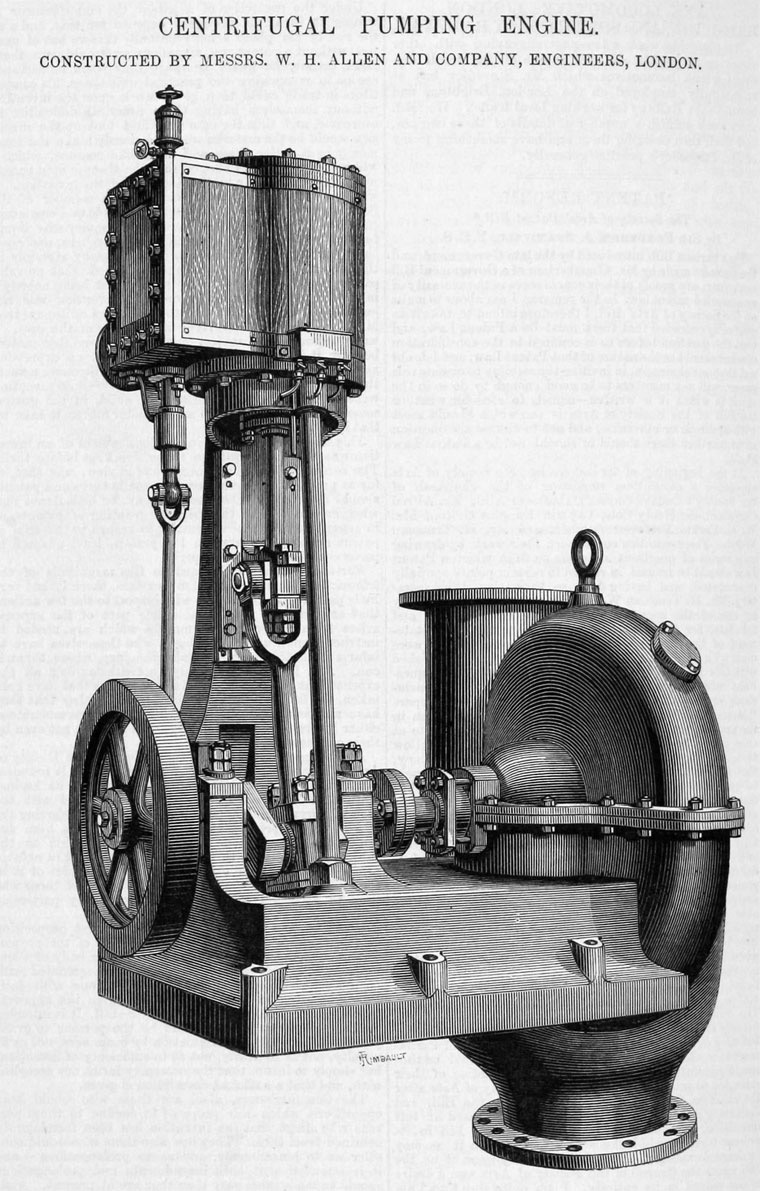

MODEL CENTRIFUGAL PUMPS.

Nos. 1, 2, and 3.

_________________________

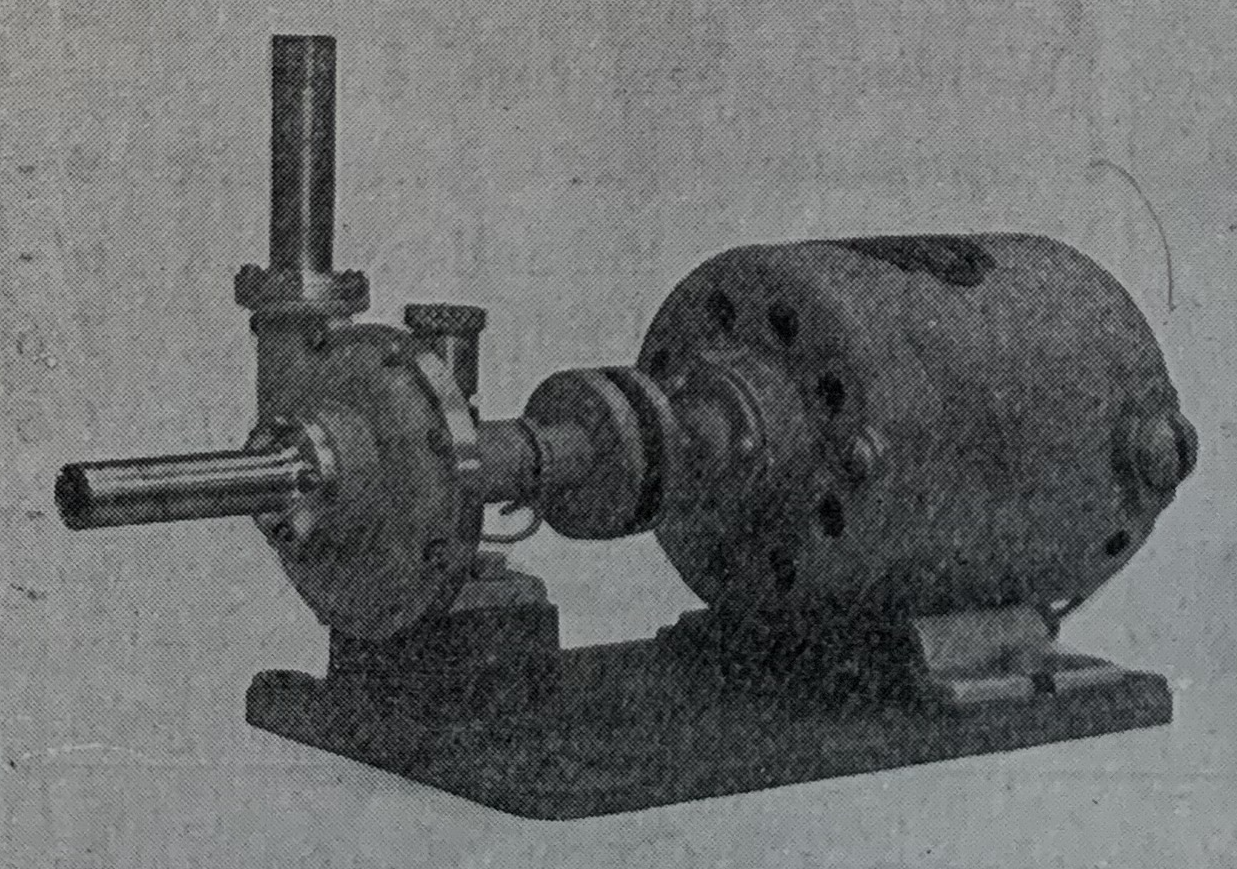

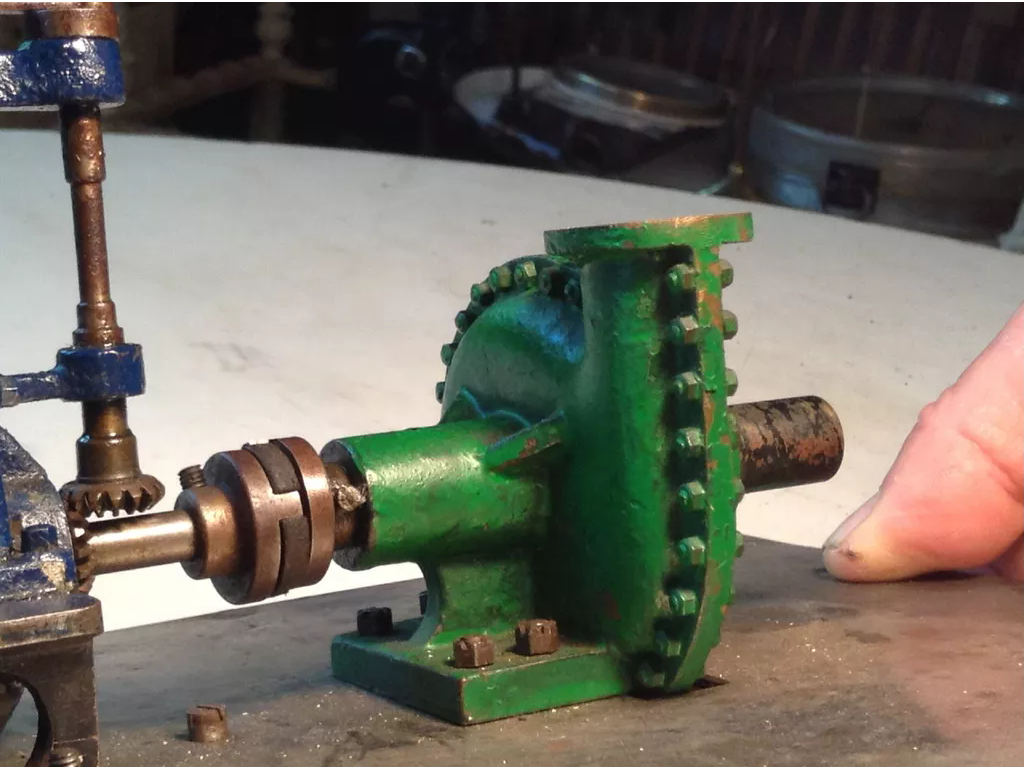

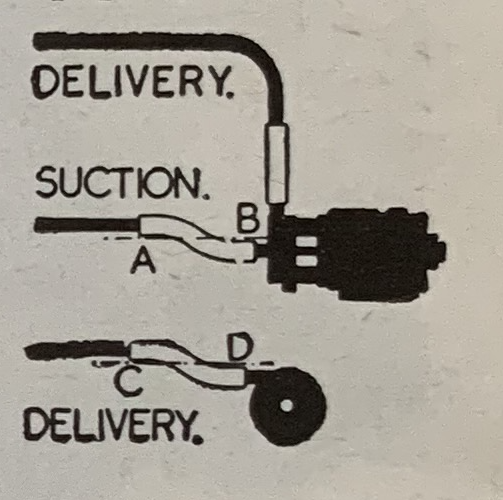

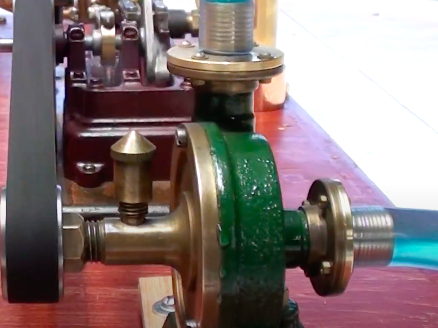

A very competent centrifugal water pump capable of real world pumping solutions. The main body is two half castings with a cast rotor fitting between. Water is sucked in the pipe central on one of the main body castings and exits out the other pipe cast into the main body directed upThe original design has the body castings fairly symetrical. Later Stuart changed the design to a main body casting and a plate casting. The second type is detailed below. Another company sold a very similar pump to the second design but reversed the sides the shaft and water inlet were mounted. I have included a video of this pump as I couldnt find a stuart pump video, I have owned the stuart and copy and they are pretty much exactly the same size.

MODEL CENTRIFUGAL PUMPS

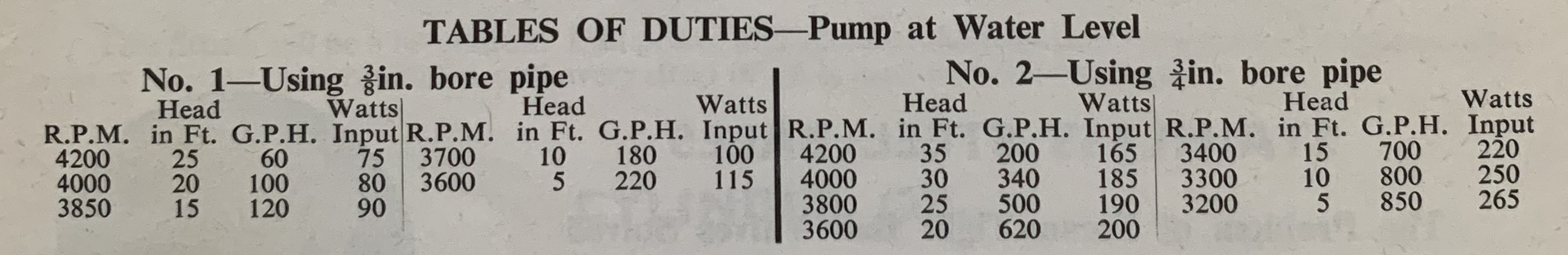

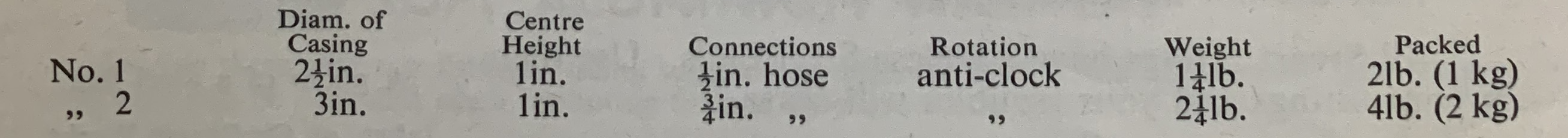

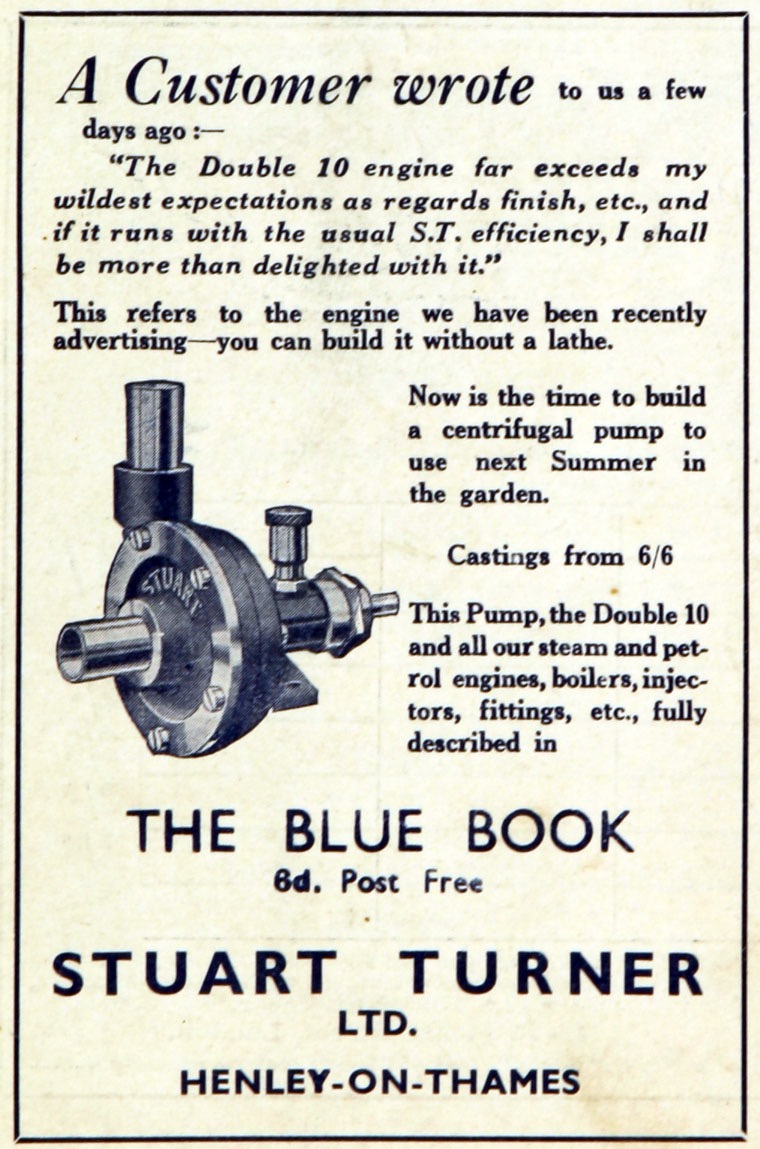

Two sizes:—No. 1 with 2in. rotor, and No. 2 with 23in. rotor.

They are designed for direct coupling.

For pumping a large volume to a moderate height the Centrifugal Pump is unrivalled. It is not capable of great suction lift, for this and for high heads a Stuart Piston Pump should be chosen. For details of these and complete electric motor driven pumps ask for List CP4m.

Pumps are often required to run for long periods without stopping; in such cases Stuart Pumps give wonderful service.

There are no valves and nothing to get out of order. The construction is a simple straightforward lathe job and a most pleasurable one.

Specification

Best quality Gunmetal with balanced impeller—rustless steel spindle running in long gunmetal bearing which is fitted with screw-down grease lubricator and gland.

Spindle diam.: No. 1, 4in.; No. 2, ~,in. Connections are for rubber hose. The pump body can be rotated so that the delivery is horizontal.

Finished Pumps of this design are not supplied.

We supply the Complete Set of Drawings, Materials, Screws, and Lubricator.

Brass Foot Valve and Strainer is available at extra cost.

Centrifugal Pump & S50

A very close copy of the later design Stuart pump. Its the same size but has the pipe on the small body casting and the drive shaft on the large body casting. I have owned the stuart and this copy and the impellor is pretty much the same size.

Please Consider Making a Donation