- © 2018 Steve Allen Contact Me 0

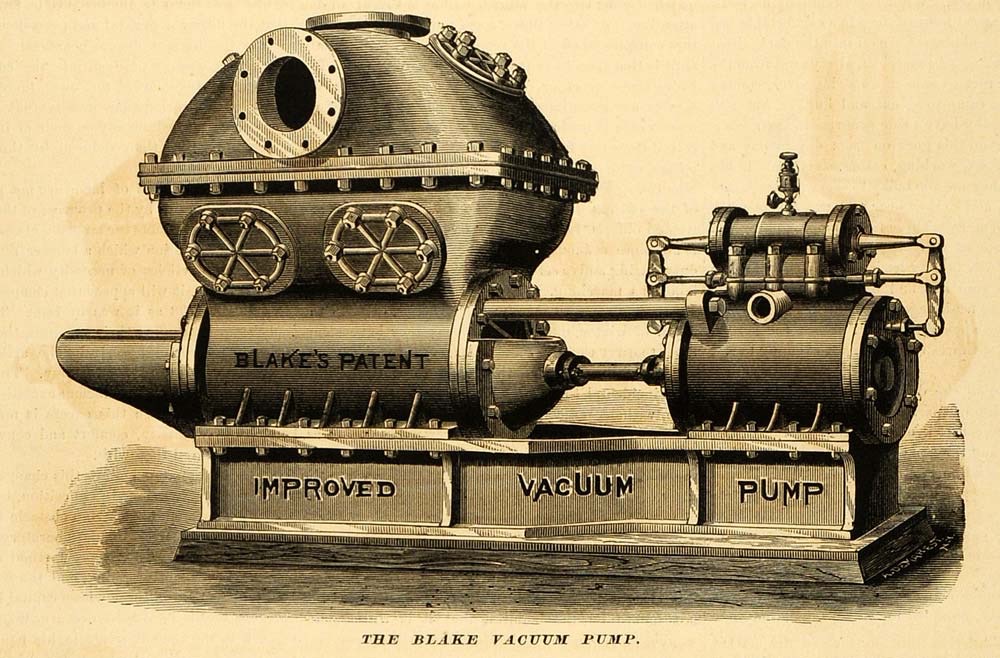

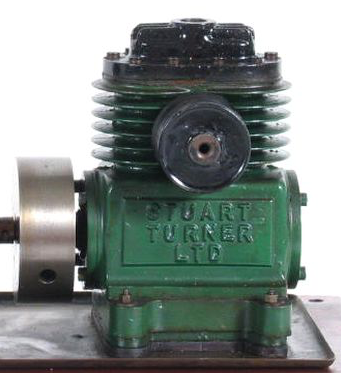

STUART COMPRESSOR

or VACUUM PUMP

TWIN SINGLE ACTING CYLINDERS 1-in. x 1-in.

Weight … … … … … … 5 3/4-lb.

Height … … … … … … 5 1/4-lb.

Length of crankcase … 4 1/2-in.

—————————

Theorectical displacement 2,200 cu. in. (1 1/4 cu.ft) per min. at 1,400 r.p.m. For pressures up to 60-lb.

————————-

The compressor has the same general dimensions as the "SIRIUS" engine and is of equally sturdy construction. Air enters the cylinders through ports in the cylinder walls and is discharged through spring controlled valves in the cylinder head. The lubrication is by splash, a dipstick being provided to show oil level.

In a compressor, it is essential to keep the air clean and free from oil, therefore there are four rings on each piston, the ring at the bottom being a scraper. For the very best results, cylinders are honed and pistons lapped in.

Noise made by even the lightest disc valves can be surprisingly penetrating. We have recently been able to lessen this noise quite considerably by modifying the shape to provide line contact. The noise is now not at all obtrusive. The machine can be used either as a compressor or a vacuum pump.

Stuart Vacuum Pumps are extensively used in hospitals and research laboratories.

Castings and all materials with 8 piston rings, valve plate ground dead flat, ball bearings, valve springs and all screws :—

£4 5s. 0d

The Finished Compressor or Vacuum Pump

£14 10s. 0d.

Foreign Orders should include remittance for 12-lb. Postage

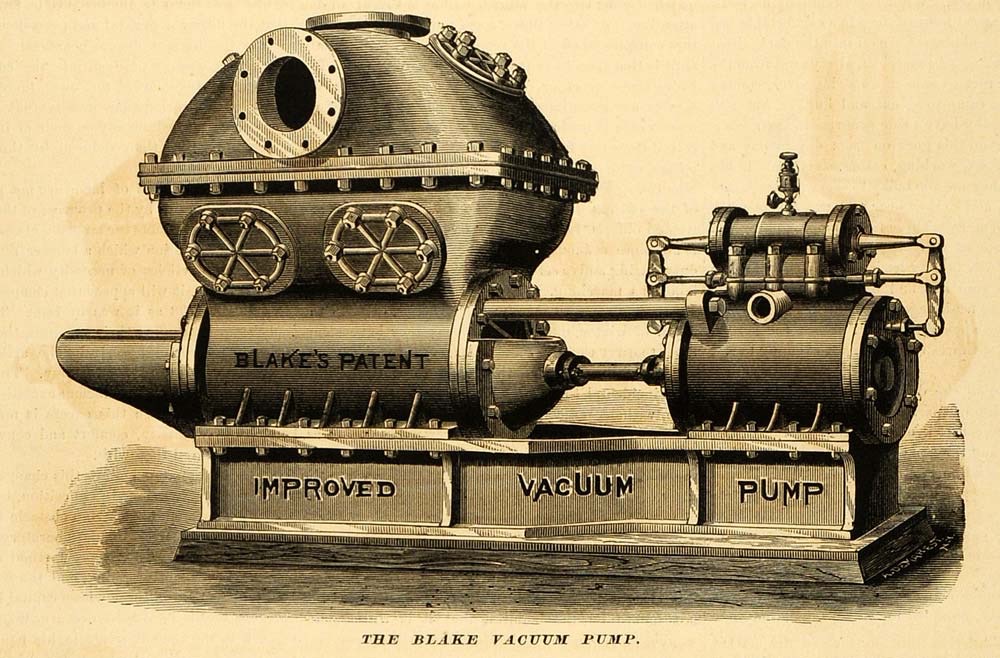

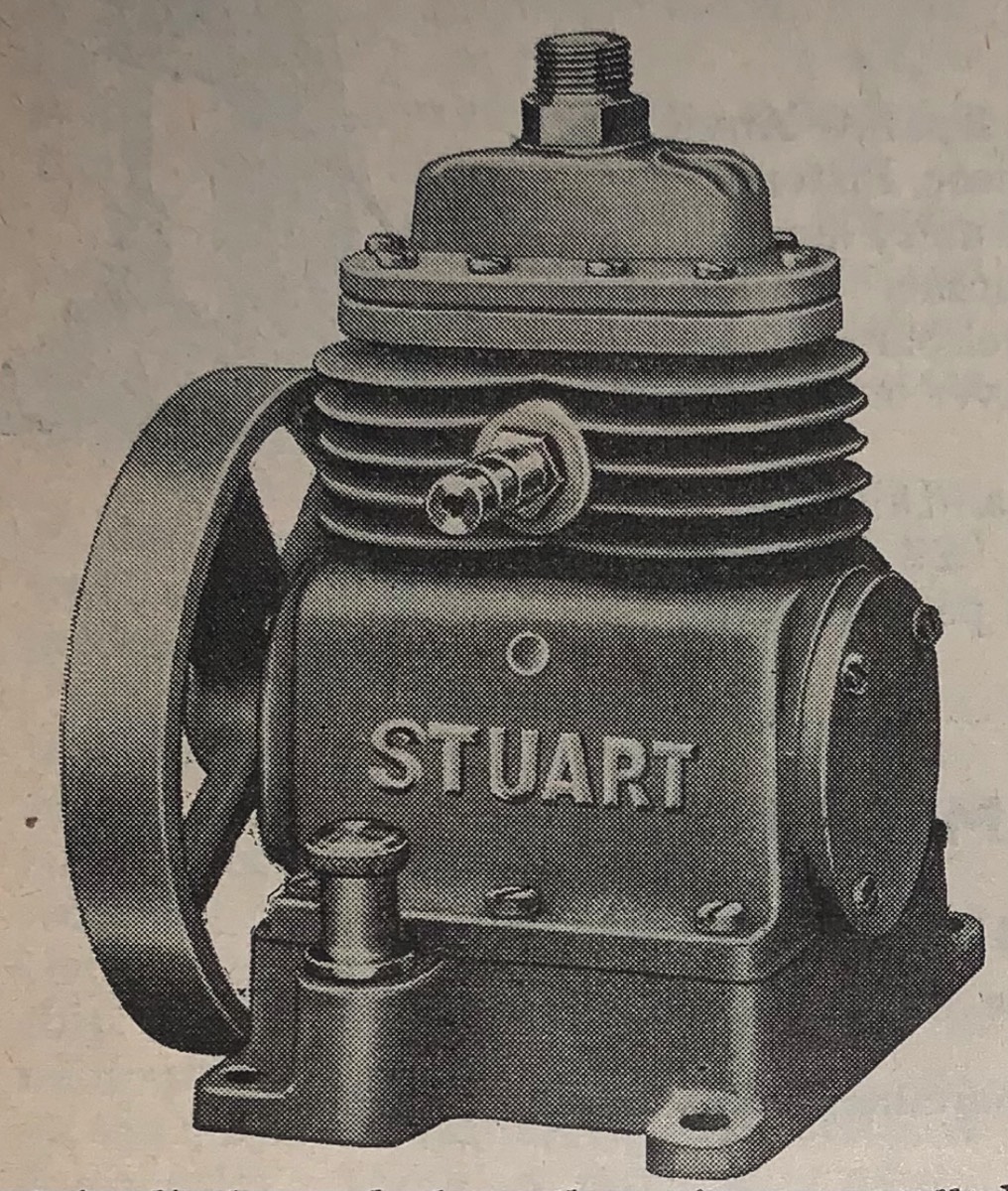

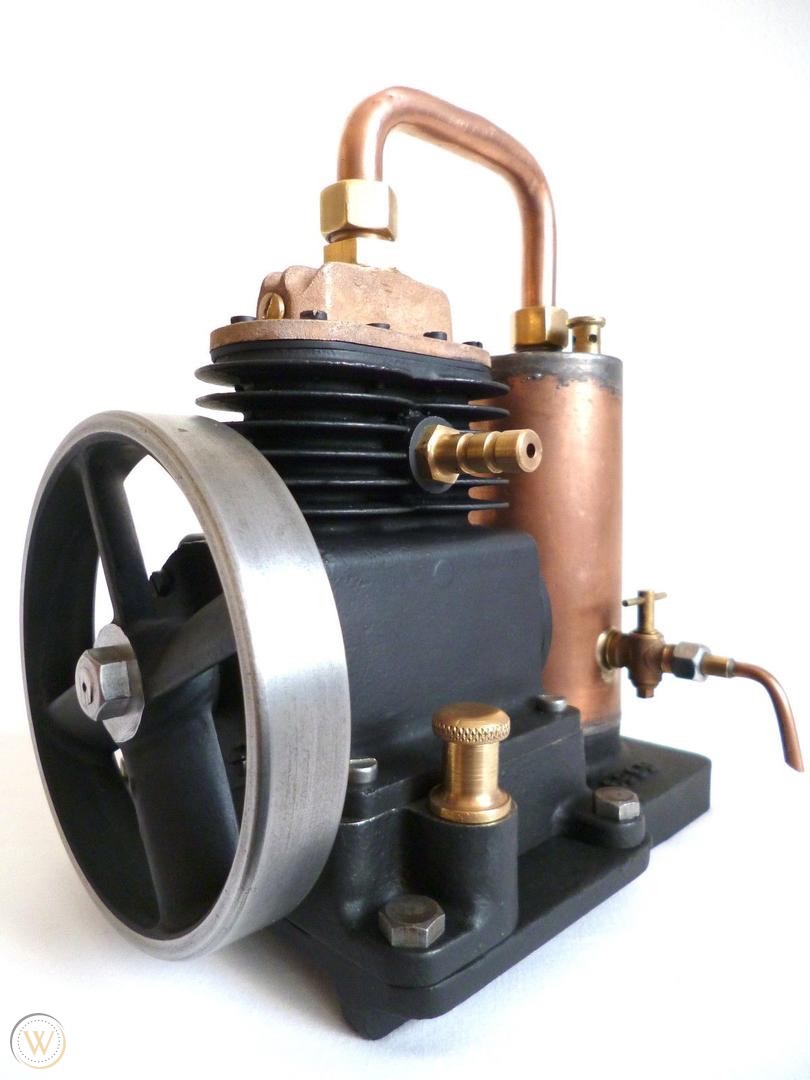

The design is not unlike the Sirius engine. The base is is used as an oil sump with blades fitted to the bottom of the big ends splashing the oil around. A dip stick is fitted to a bulge in the casting and a drain plug is also fitted to some compressors, but not all. The main body mounts the dual ball bearings that support the crankshaft. A blank plate covers one end of the crankshaft, and the opposite end is drilled to allow the crankshaft to extend out for the pulley. A woodruff slot and key is used to hold the pully on the crankshaft. The pulley is unusual in that the spokes are modeled to be fan blades blowing air over the cylinders. The cylinders are cast to include cooling fins as compressing air creates a lot of heat. Between the cylinders on the front is mounted a hose connection or a smaill air filter. this is the air intake so only needs connecting if using as a vacuum pump which it will suck air from, so this should be of a non collapsing type hose. The Cylinder head does not contain the valves, instead a thin steel plate fits between the cylinder block and the head. This can be seen in the image below, it contains 4 holes for each valve whish is spring loaded. Operation is simple, at the bottom of the piston stroke air passages connecting to the air inlet are exposed allowing air to enter the cylinder, as the piston rises this is closed and the trapped air is compressed raising the spring loaded valce at the top of the cylinder. Once the piston reaches the top of ts stroke the val closes and as the piston descends a vacuum is formed in the cylinder until the air inlet passage is exposed and air rushes in. So compressed air is forced out a connection at the top of the head. so a presurised air vessel is connected to the top fitting.

The compressor uses some similar castings to the Sirius. The main body casting is the same with cooling fins and ball bearings added, the pistons and crankshaft are the same. The base is similar. A new valve plate has been added to hold the sprung loaded button valves. The top casting is similar shape but is not bulged as the piston valve is not there. A new flywheel with four spokes shaped like fan blades forces air over the cooling fins.

Video Of Compressor

Thanks to Ted Schnack for sending me this video of his Compressor being run by a Sirius.

Please Consider Making a Donation