- © 2018 Steve Allen Contact Me 0

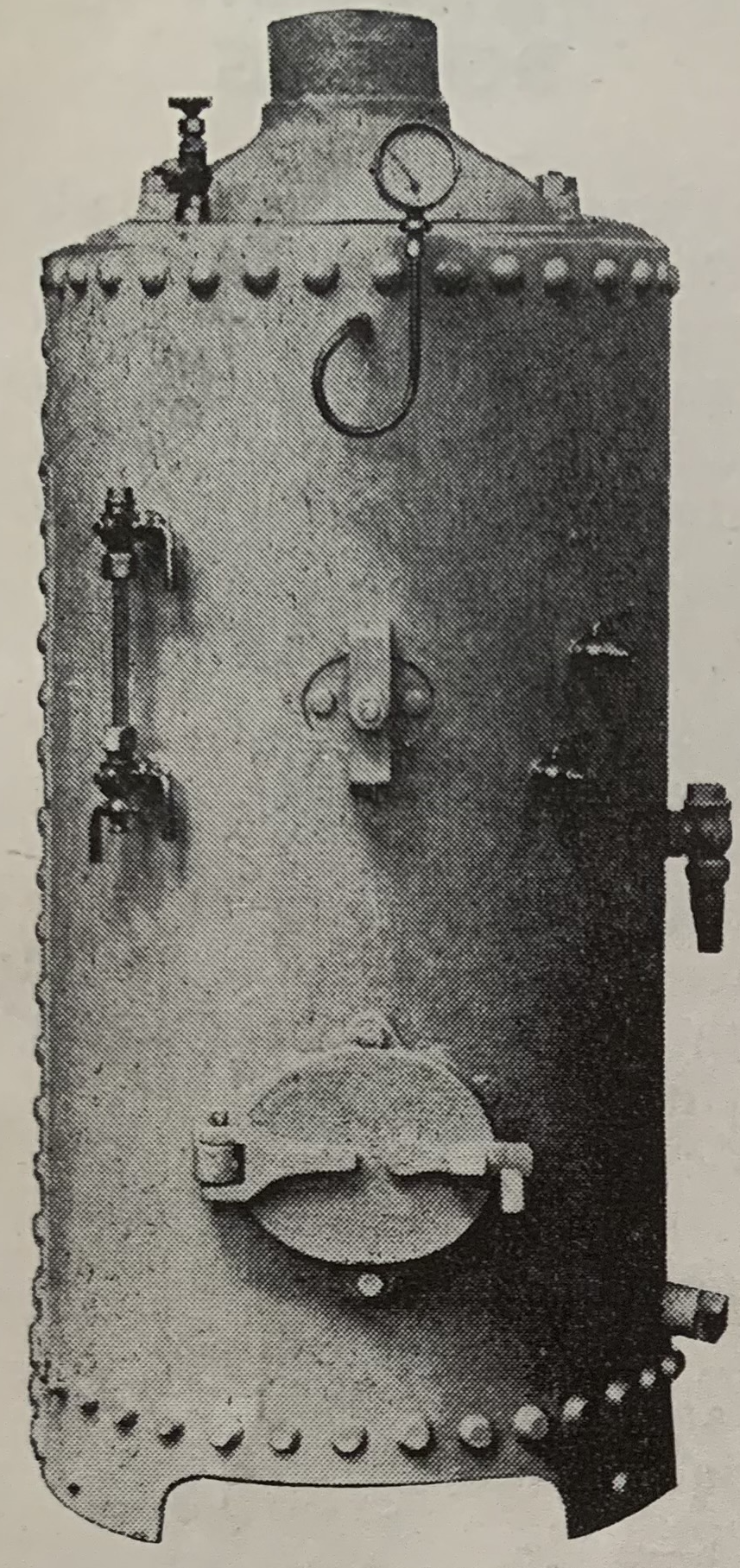

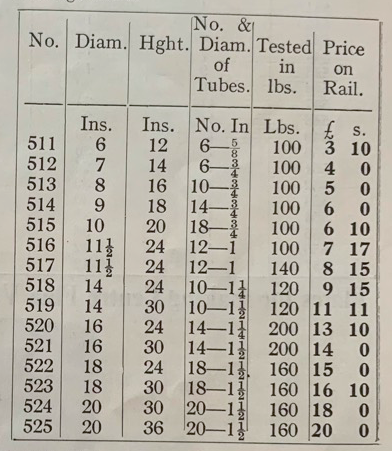

VERTICAL STEEL

MULTI-TUBULAR BOILERS

For Solid Fuel

add P/Tax

The Shells of these Boilers are made of best Open-Hearth Mild Steel, with flanged ends, Steel Tubes, Firedoor, Fire-bars and Smoke Box. Water space all round fire. Manhole fitted for a small extra charge. Fittings and Chimneys extra.

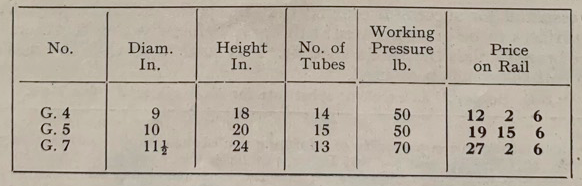

GAS FIRED MULTI-TUBULAR BOILERS

These are Steel Boilers complete with gas burners and smoke box. A gas-fired Boiler is a most convenient form of steam generator : it is ready for instant use, is clean and safe and is easily controlled.

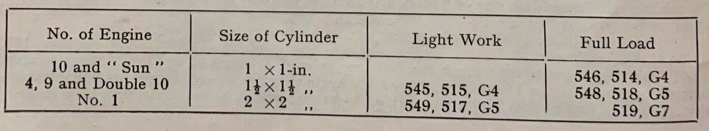

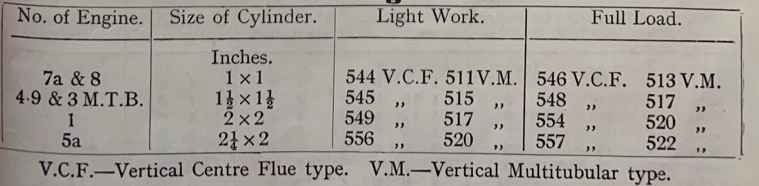

Vertical Boilers to suit our Engines

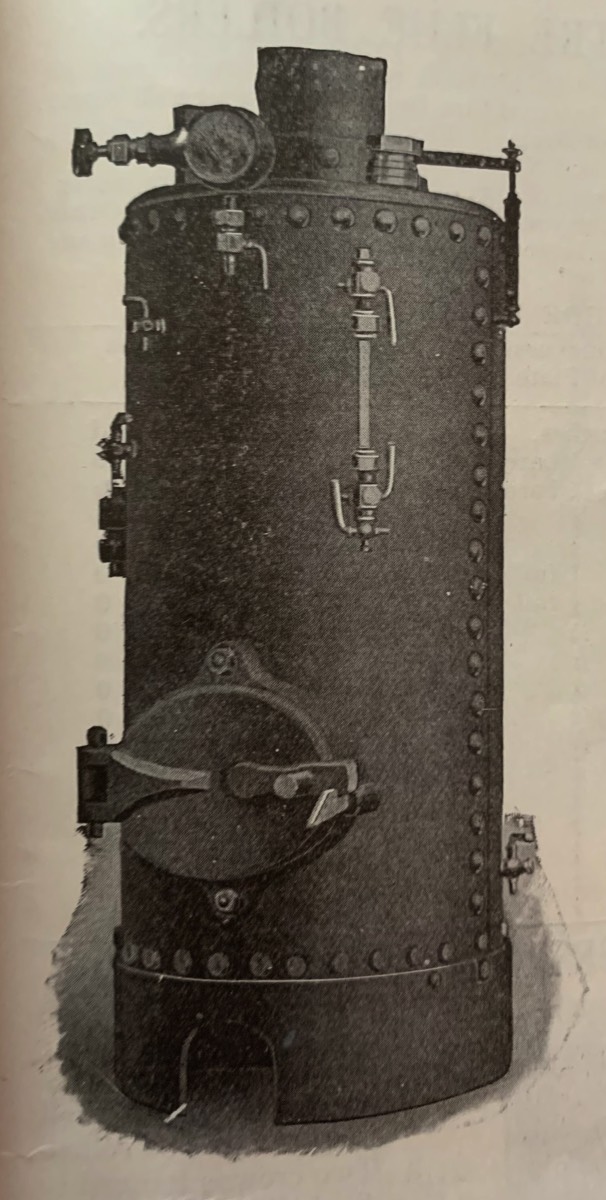

VERTICAL STEEL CENTRE FLUE BOILERS

Specifications-“Mild” Steel with steel rivets, all holes drilled after plates are bent to shape. Water space all round fire. Cast Iron Door and Frame. Fire Bars.

Manholes can be made in Nos. 545 to 548 at extra charge of 17/6. Chimneys extra according to height required, including half-round ring at top.

Any of these Boilers can be made in Copper if required. Prices on application. Prices on application.

PRICES DO NOT INCLUDE FITTINGS

Plates for making Centre Flue VERTICAL STEEL BOILERS.

Stuart really have covered vertical boilers in all possibilities. Sold as a kit of parts or a completed boiler the materials can be steel or copper. Whilst steel is stronger it should be inspected internally to check for rust, hense the oprion of a manhole fitted to allow viewing the interior. Copper whilst not as strong does not suffer from corrosion to the same degree. Stuart also offered a Brazing option for the boiler you supplied, metioning the importance of not soft soldering as this precludes brazing as well as silver soldering.( probably the best method of construction) Rivetting was also an option that requires very close tolerances. Firing using coal gives a very hot flame that boils well but requires a certain patience to get going. The fire door and grate is required to allow drawing the flames. Vertical boilers offer large steam producing capability with low footprint. The ability to be coil fired allows for the real steam enthusiasts to enjoy the process of setting up a fire and keeping it fuelled. Gas offers convenience with a simple burner fitting underneath. Fittings available covered just about everything you could want. Pressure gauge, water gauge, Klack valve, Steam valve, Safety valve,.

Please Consider Making a Donation